Safety

Product description

Scope of delivery

Specification

Installation

Flushing and venting

Electrical connection

Electrical connection GB

Installing the external sensor

Operating panel

Delivered condition

Setting the control mode

AUTOADAPT mode

TEMPERATURE+ mode

Resetting to factory settings

Service and replacement

Faults and remedies

Disposal

Declaration of conformity

Contact

These instructions apply to all specified product series and describe safe and appropriate use at all stages of operation.

Warnings and symbols

General safety information

- Installation, electrical connection and commissioning of the pump may be carried out only by qualified contractors and all general and local safety measures must be observed.

- Operating instructions and associated documents must be complete, legible and accessible at all times.

- Before carrying out work on the pump, read and ensure that you understand the operating instructions.

- This circulation pump is suitable only for water of potable quality.

- The pump should be operated only if it is in technically perfect condition. It must be used only in accordance with intended use, with an awareness of safety and risks, and in accordance with these instructions.

- Before any installation and maintenance work, disconnect the motor from the power supply and secure against reconnection.

- The use, cleaning and maintenance of this device by children aged 8 years or older, persons of restricted physical, sensory or mental capabilities, or persons with limited experience or knowledge is permitted only if they are supervised or instructed in the safe use of the device and understand the associated risks. Children must not be allowed to play with the device.

COMFORT pumps are efficient circulators designed for hot water recirculation in residential buildings.

These pumps feature a compact design housing and high-performance permanent magnet with an integrated control unit. The spherical rotor, equipped with an impeller, ensures optimal functionality, supported by a robust single-bearing ball system. The pump housing, crafted from drinking water approved brass, guarantees both safety and reliability.

Equipped with external and built-in temperature sensor, the COMFORT pumps provide precision in maintaining water temperature.

Installation is easy with included cable for electrical connection.

The user-friendly interface, made with LEDs and pushbuttons on the front, offers an intuitive platform to display control modes, ensuring a comfortable and energy-efficient experience for residential use.

Operation and Control modes

AUTOADAPT mode

- The pump constantly learns usage patterns throughout the day via an external sensor on the supply pipe and ensures hot water is available only when needed.

- During the first two weeks after installation, the pump frequently starts based on temperature control to ensure immediate comfort until usage pattern has been learned.

- After learning phase, pump operates only at times when hot water usage is predicted based on learned usage patterns. Pump operates based on temperature control in those predicted periods.

- After 24 hours of no water usage, the pump automatically enters vacation mode and resumes operation when it first detects demand for hot water.

- Once a week, when the highest water temperature in the system is detected, the pump runs a 15-minute legionella disinfection cycle. The water heater must have enabled that function once a week.

- The pump runs immediately when hot water is drawn off, at times usage pattern has not been yet learned and water temperature in pipes is cooled down.

TEMPERATURE+ mode

- When the temperature mode is enabled, the pump measures water temperature via an external and internal sensor. It automatically adjusts ON/OFF temperatures based on the maximum temperature measured in the system. For instance, if the maximum water temperature is measured at 45 °C, the pump switches OFF at temperatures above 41 °C and turns back ON when the water cools down to below 38 °C. The system's maximum temperature is measured every second.

- After 24 hours of inactivity, the pump automatically enters vacation mode and resumes operation when it detects demand for hot water.

CONTINIOUS 24/7 mode

- The pump operates continuously 24 hours per day.

For more details click on this link:

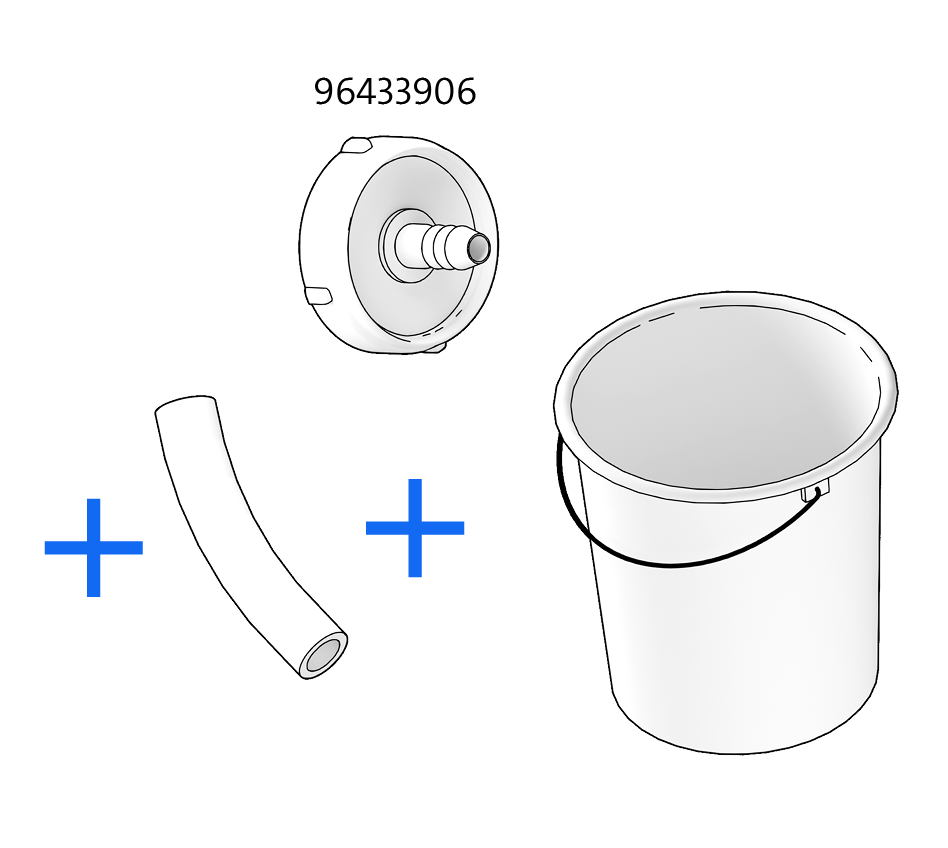

- Pump (external temperature sensor, integrated electrical cable with mains plug).

- Insulating shell for pump housing

- Quick Guide

- X variants includes shut-off and non-return valve

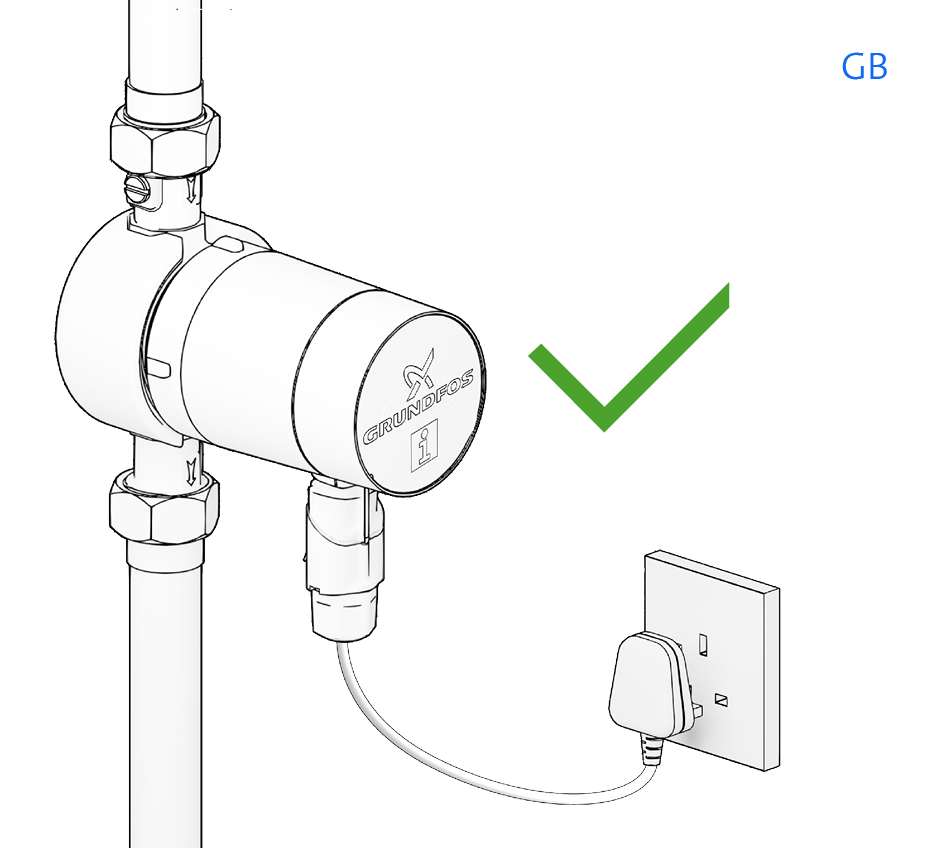

- GB variants doesn't include electrical cable and plug

Max. Flow rate

0.5 m3/h

Max. Head

1.2 m

Supply voltage

1 x 230 V / 50-60 Hz

Power consumption

5-7 W

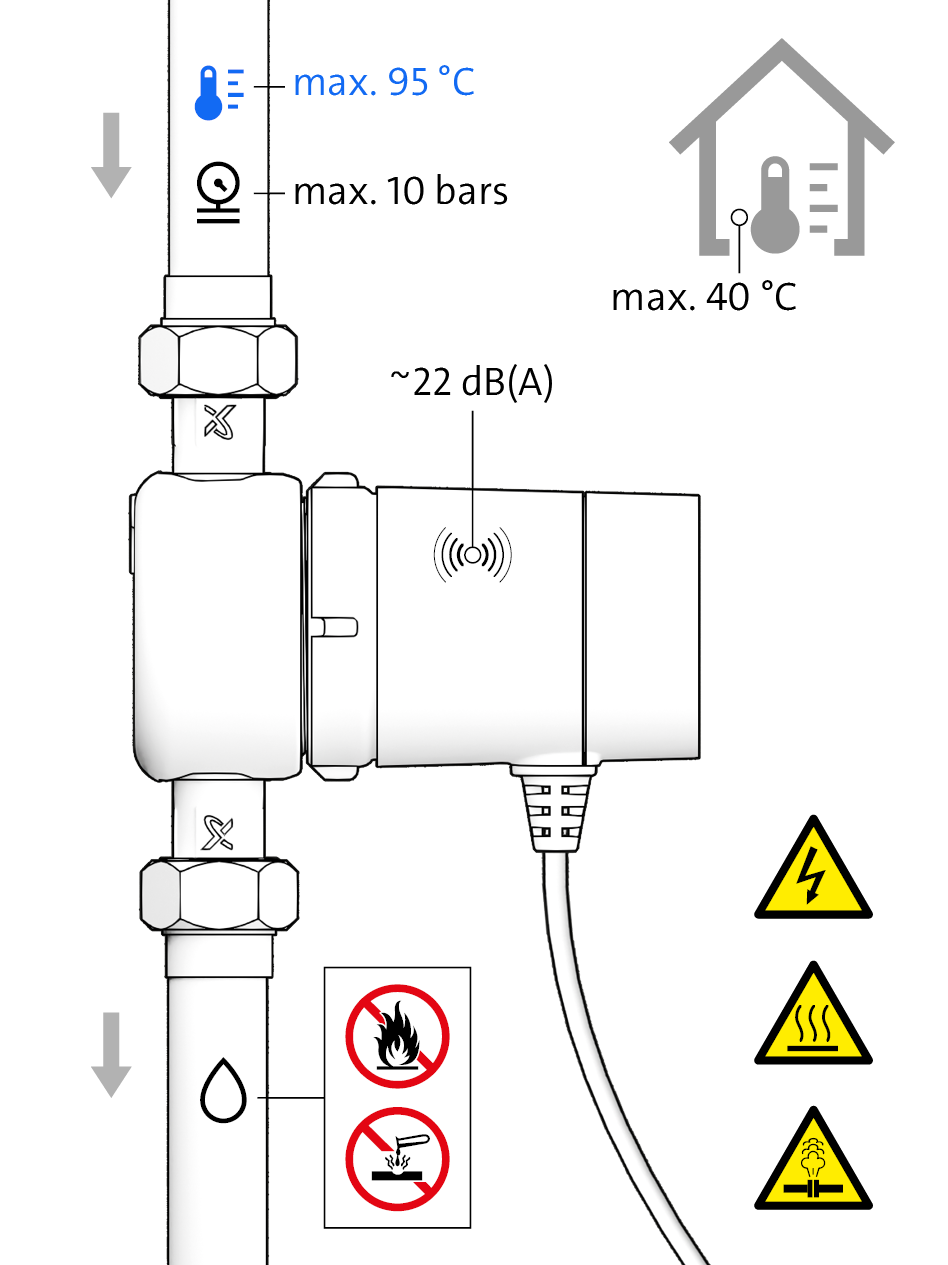

Liquid temperature

2-95 °C

Enclosure Class

IP44

Appliance Class

Double insulated

Pump housing material

Brass

Permissible water hardness

Unrestricted

Dry-running protection

Yes

CAUTION! Ingress of water will cause physical damage!

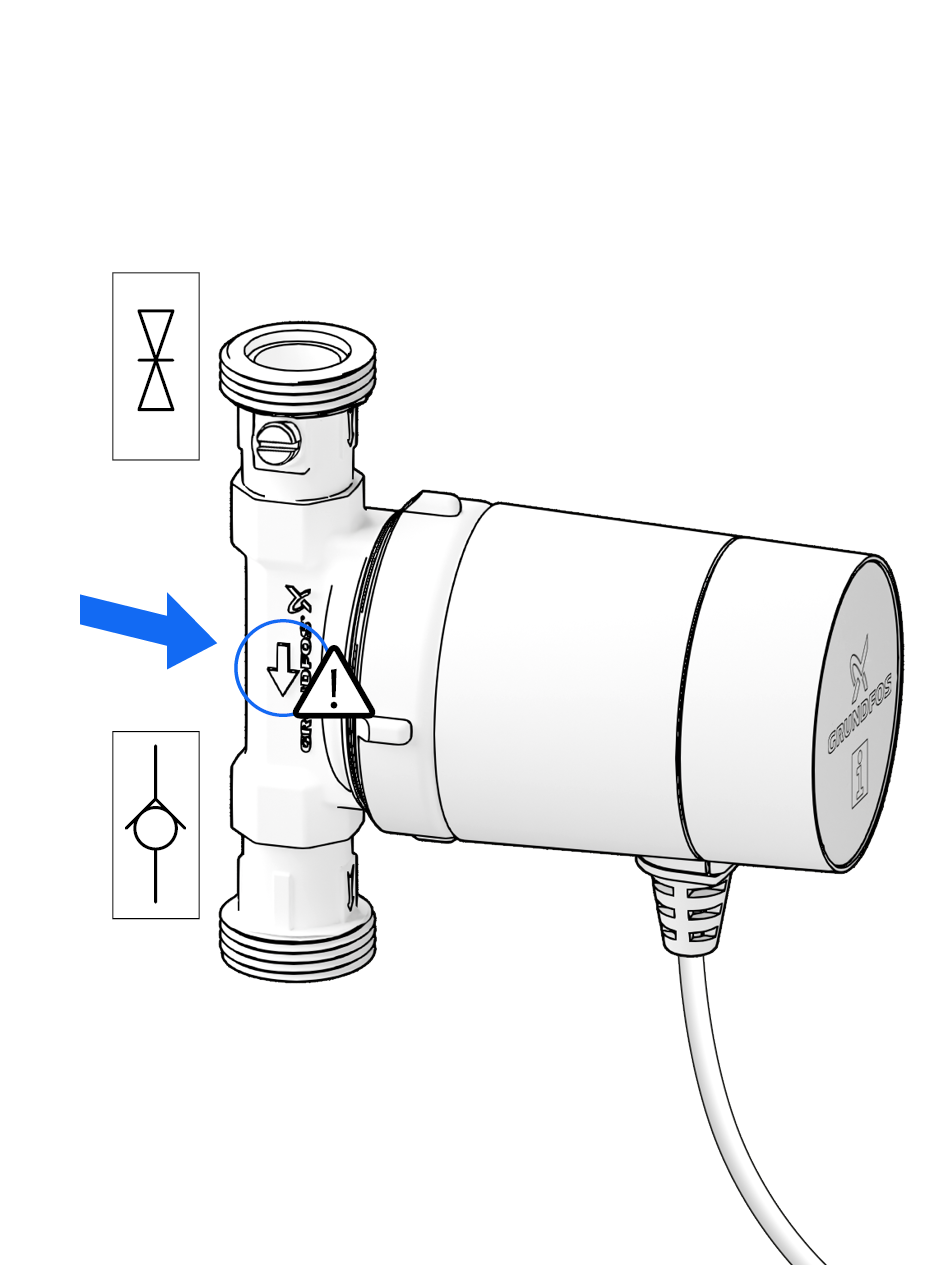

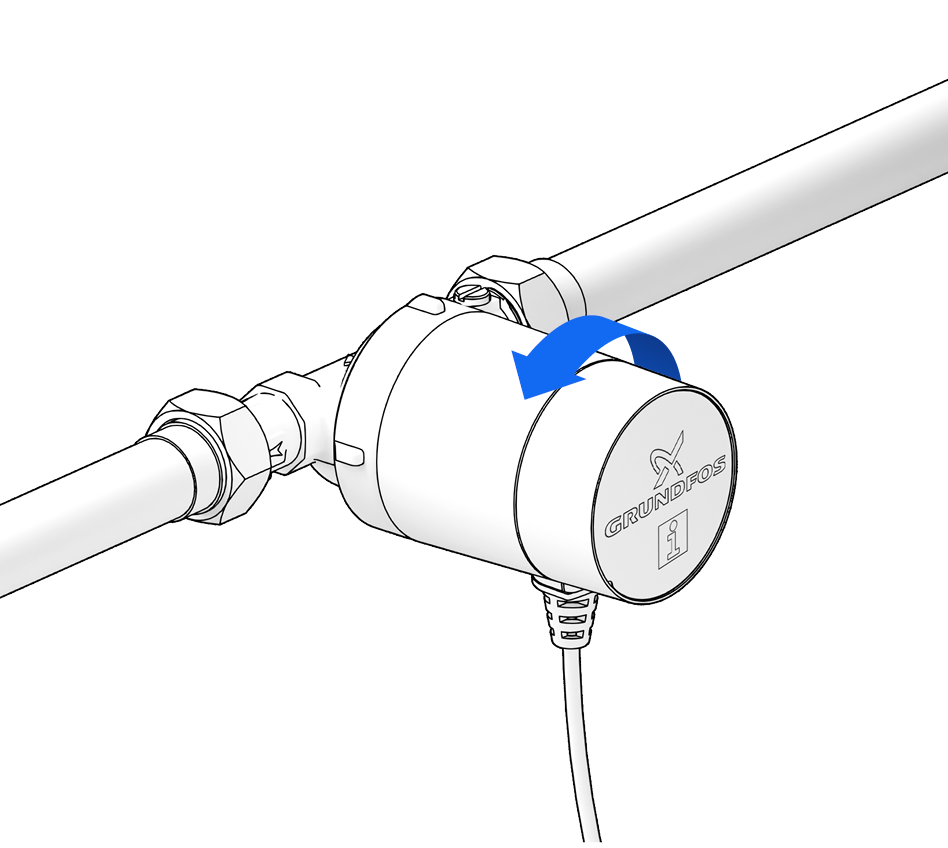

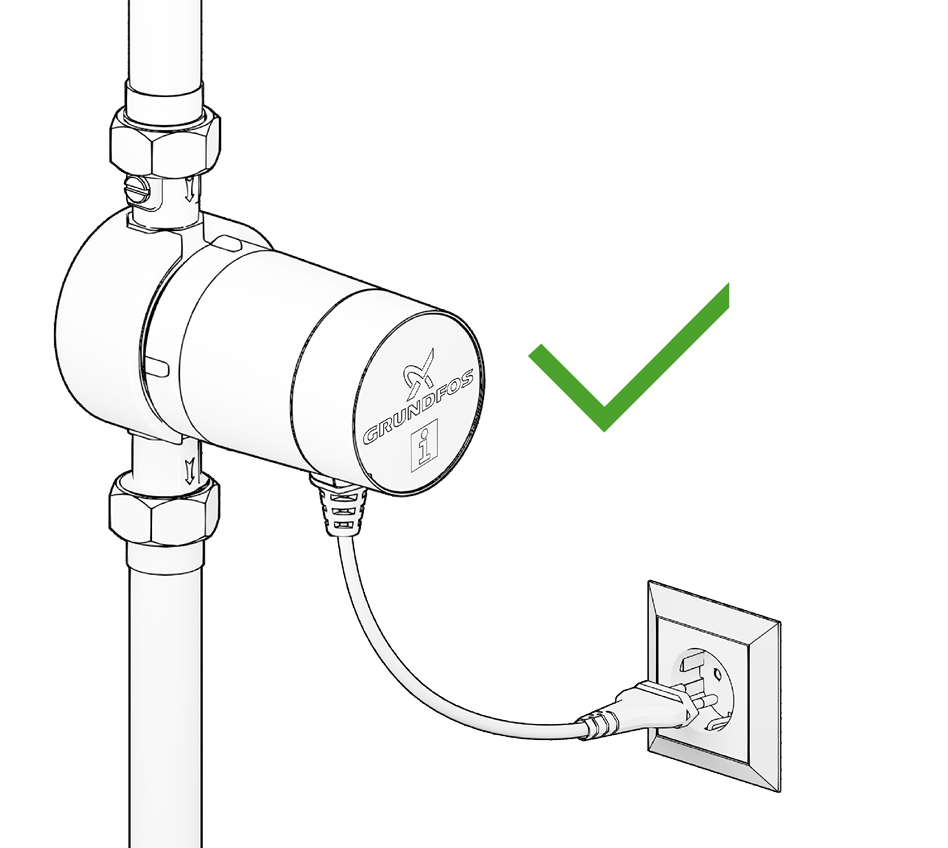

- Ensure that the cable entry and cable face downwards after installation.

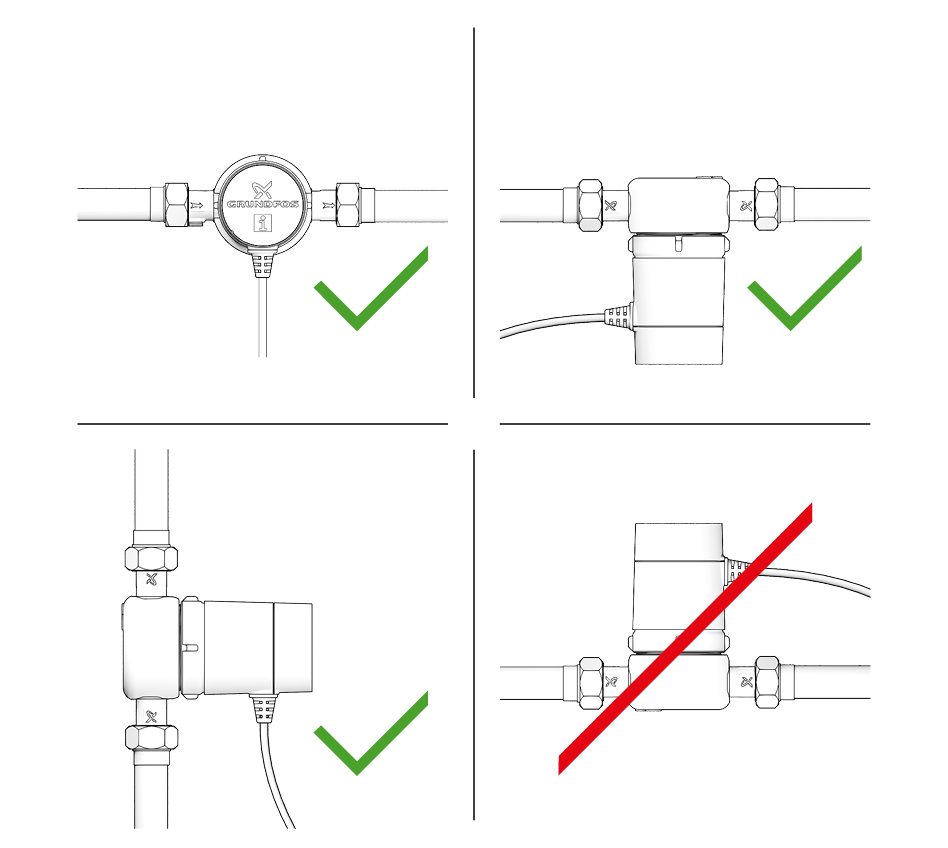

Select a suitable installation site and permissible installation position.

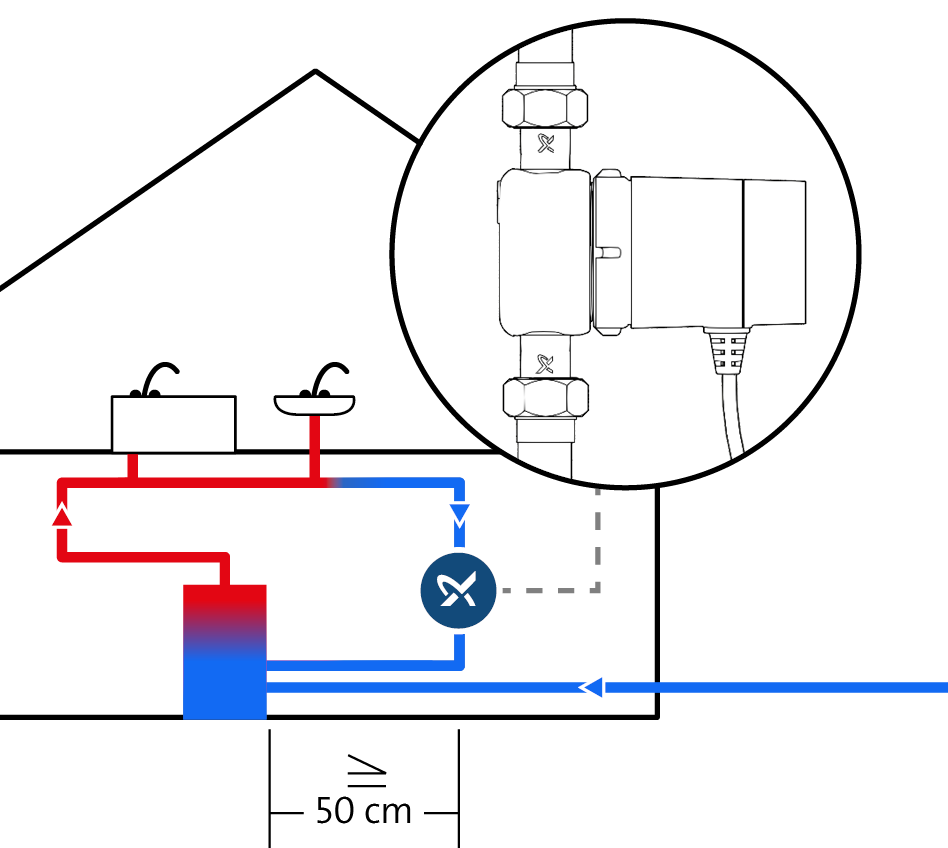

Avoid exposing pumps with temperature mode, such as the T, TDT and TA, to heat:

– Maintain a clearance of at least 50 cm from the DHW heater.

– If the return line opens vertically into the cylinder, install the pump well away from the cylinder entry.

Fit external shut-off (isolating) valves if you need to be able to remove complete pump without draining the system. Integrated shut-off (isolating) valve in pump housing is enough for motor replacement.

- If you are using additional non return or check valve, ensure that is installed in the direction of flow and that has low opening (cracking) pressure of max 0.2 kPa or 20 mbar.

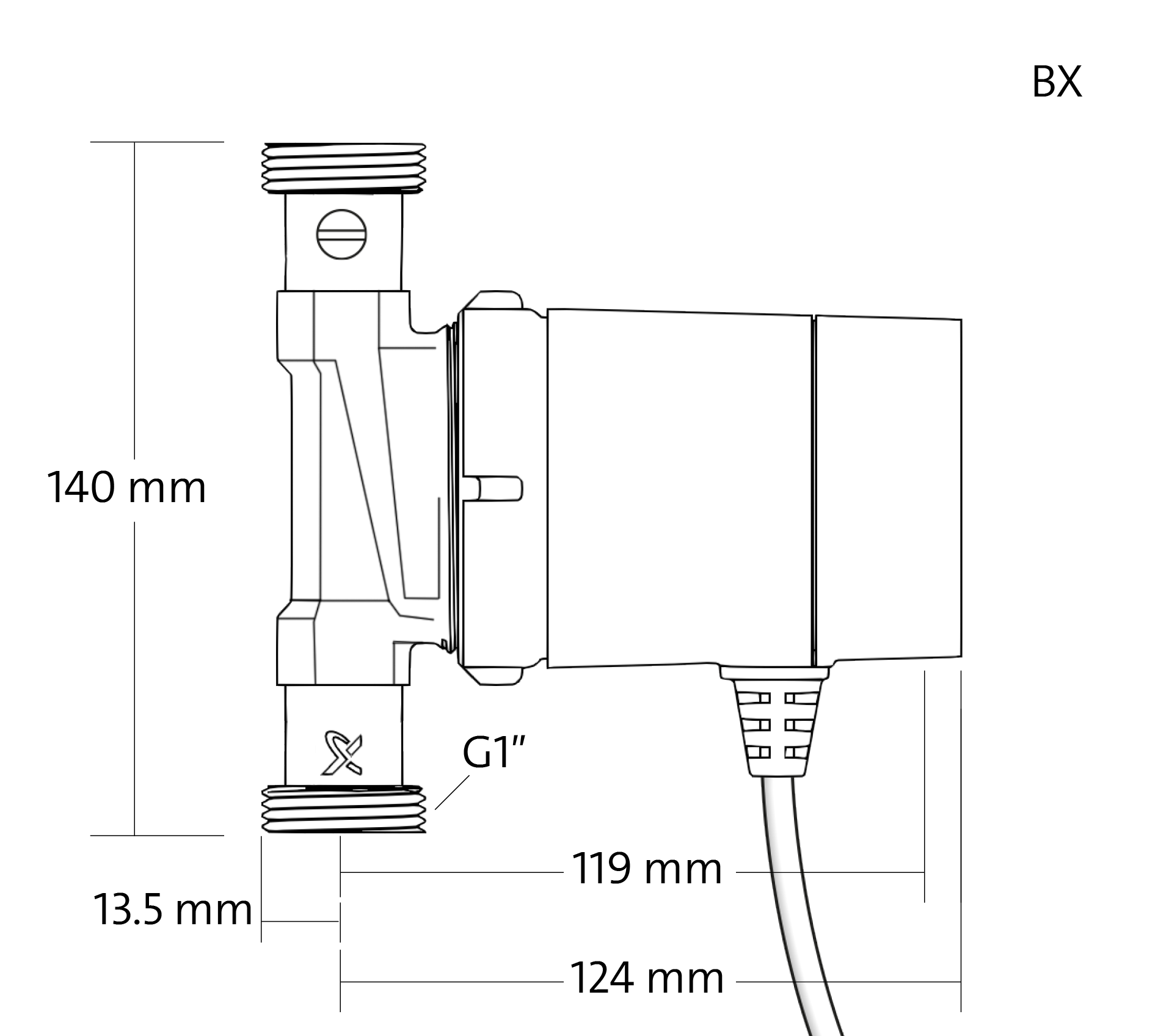

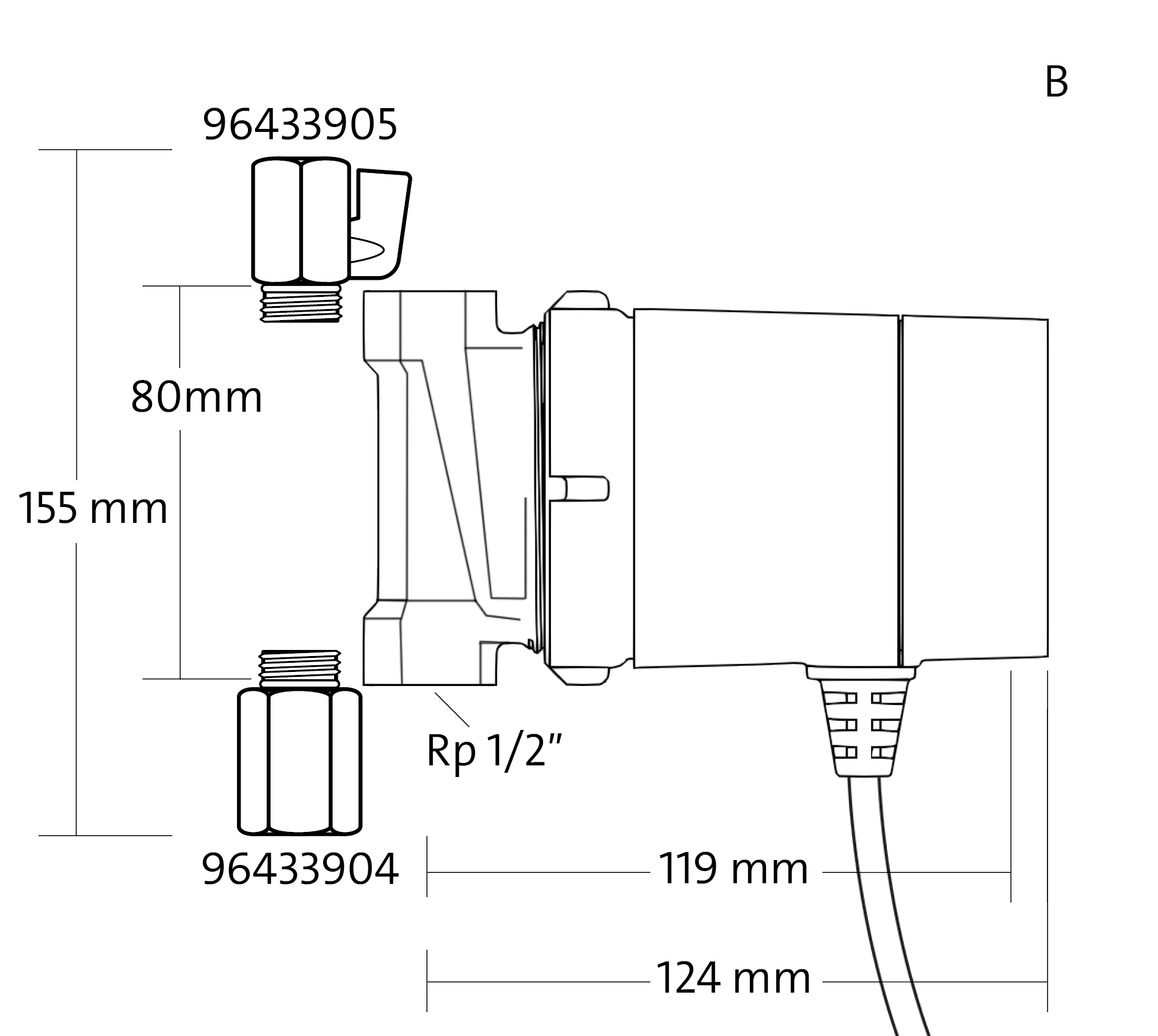

Shut off valve and non-return valve integrated. Check port to port length, connection type and other dimensions.

Option valves on B pumps. (96433905, 96433904).

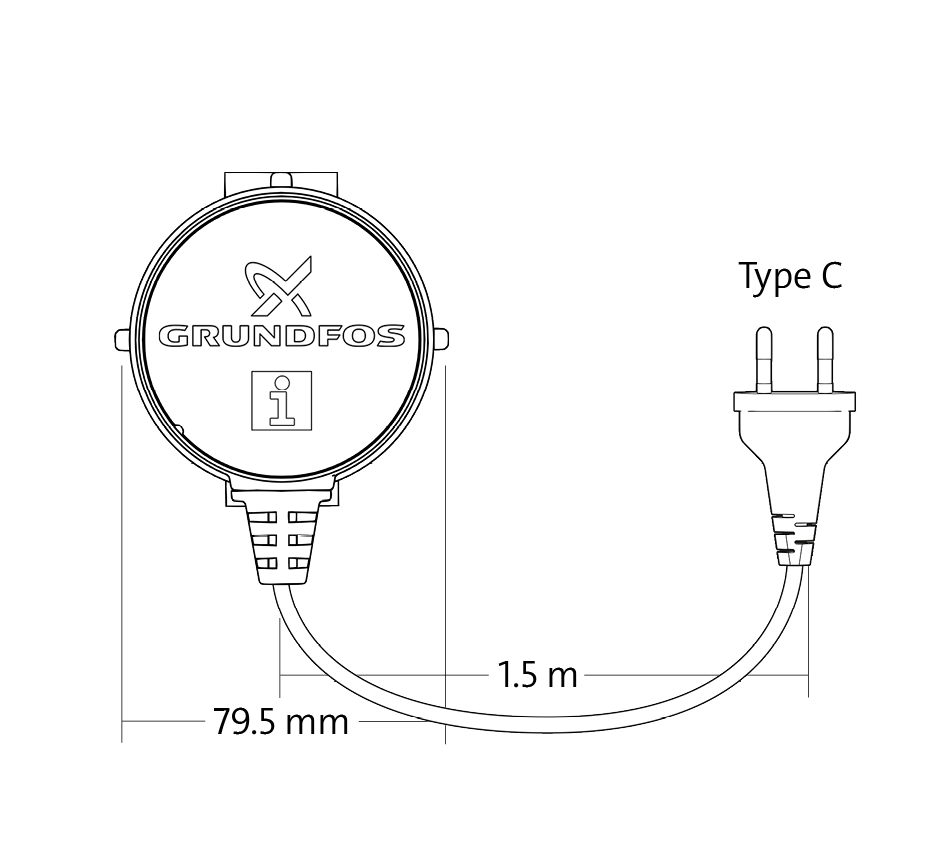

Electrical cable with mains plug included.

Note:

GB: Doesn’t inlcude cable and plug.

CN: Has plug Type A.

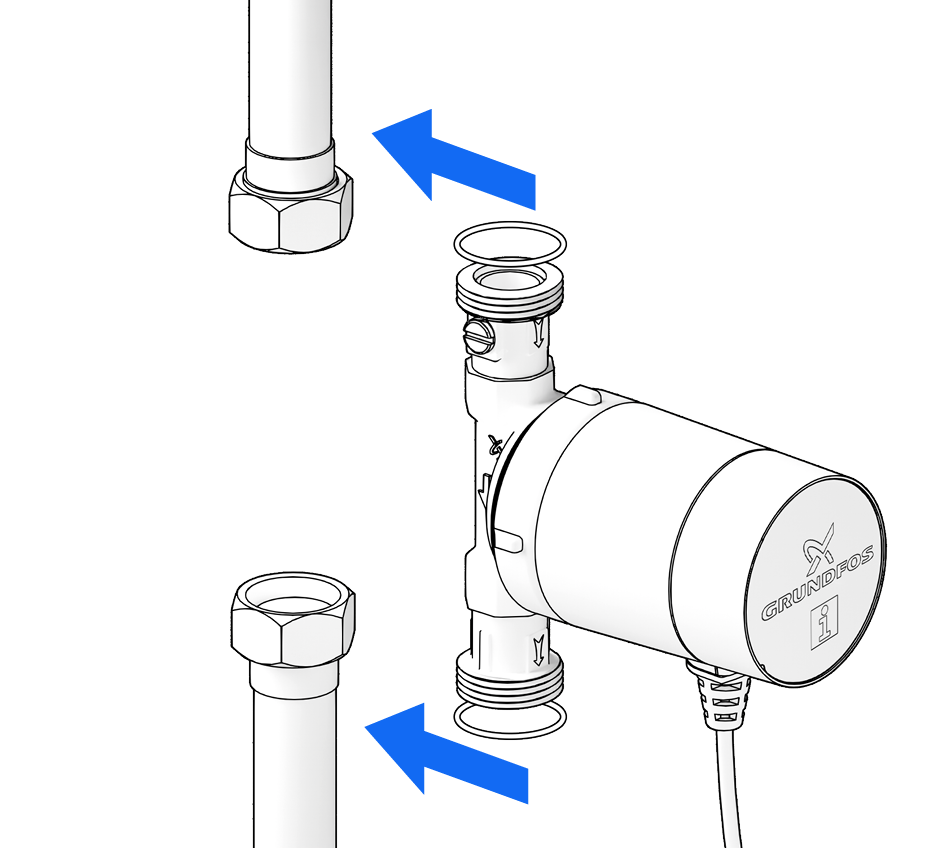

Observe correct direction of flow.

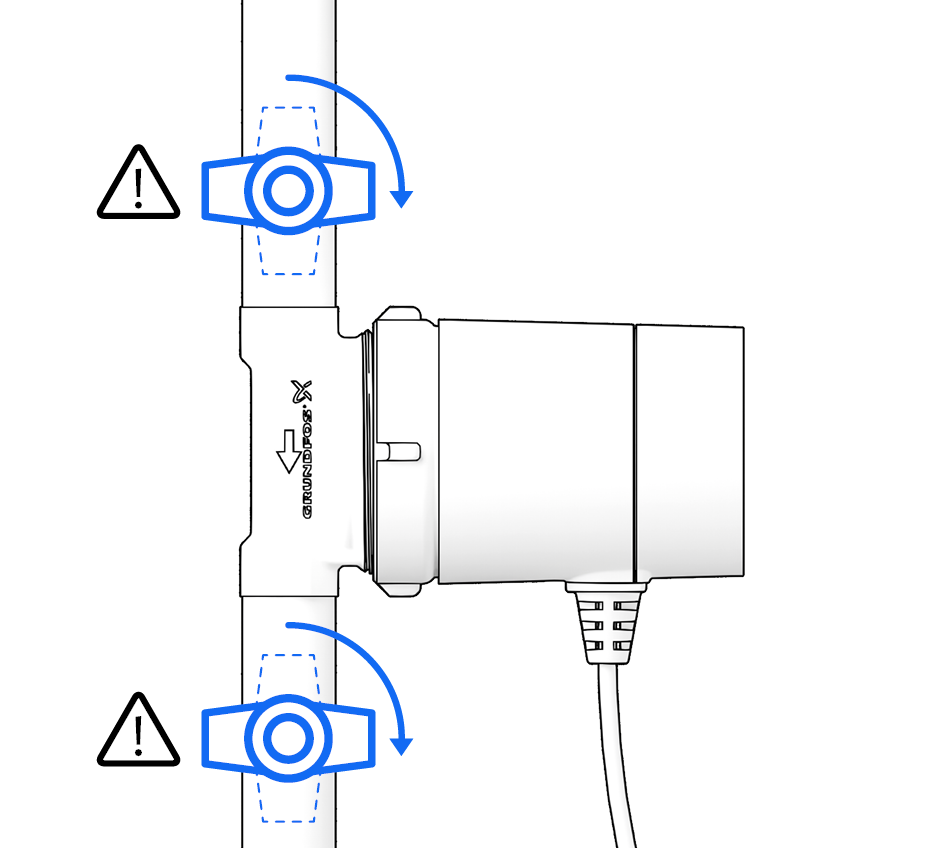

DANGER! Pressurised system!

- Before working on the motor or pump connections, close the shut-off valves.

When installing the pump, ensure that it is not under strain.

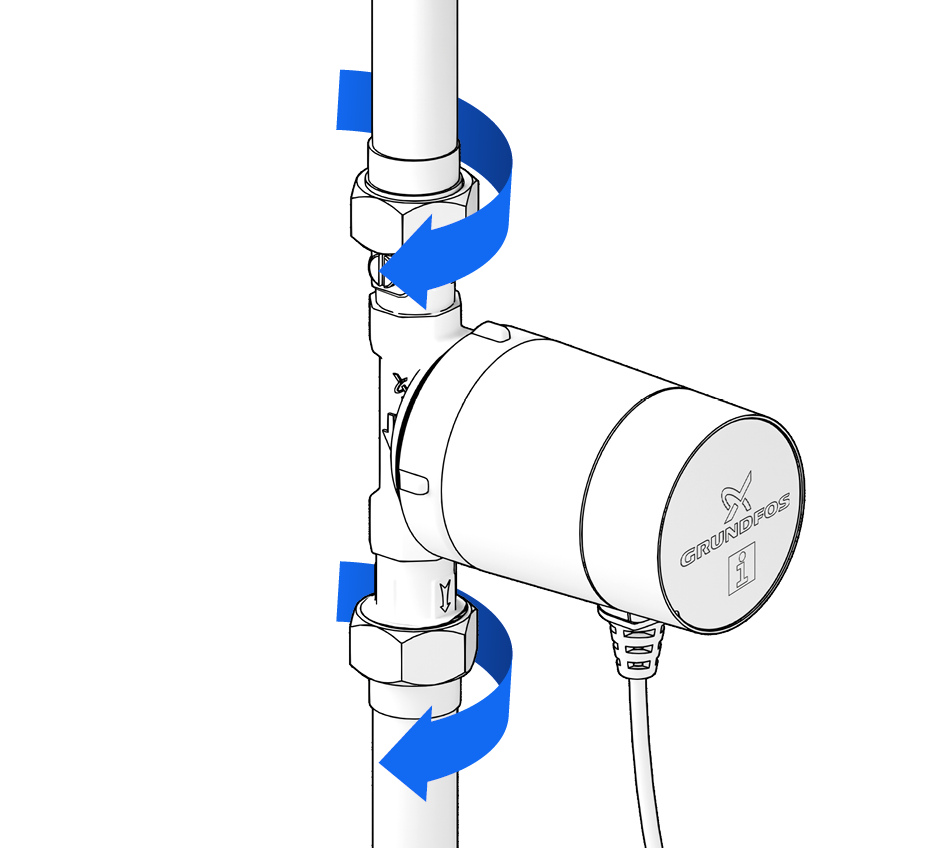

Tighten the fittings.

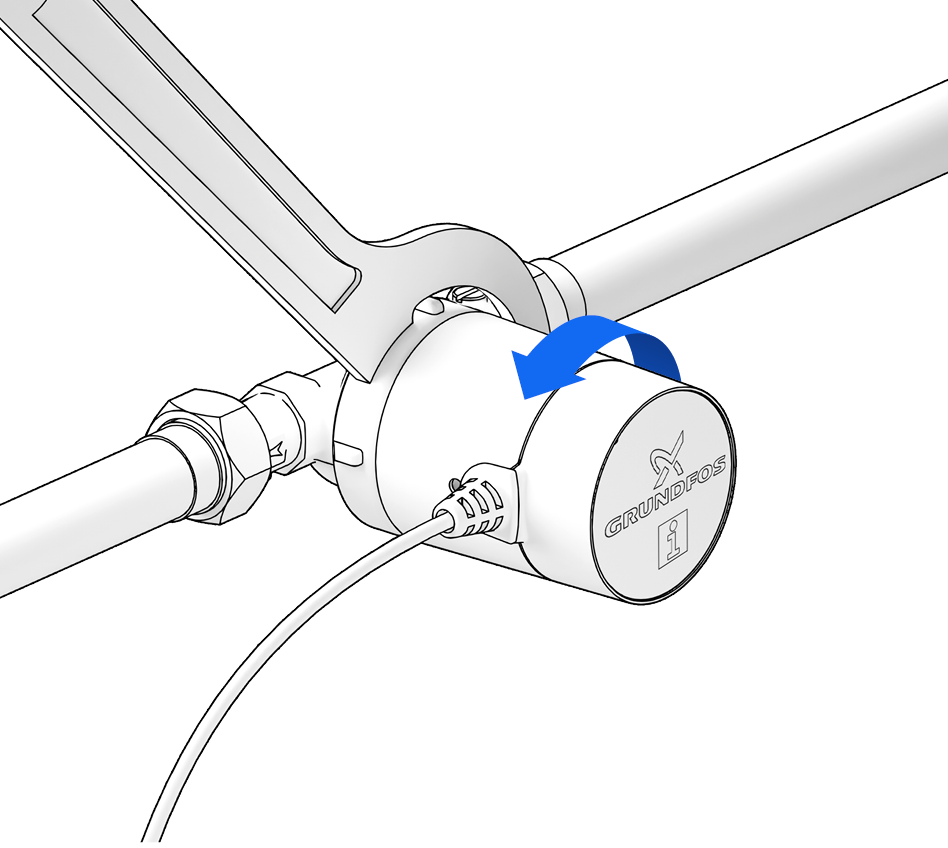

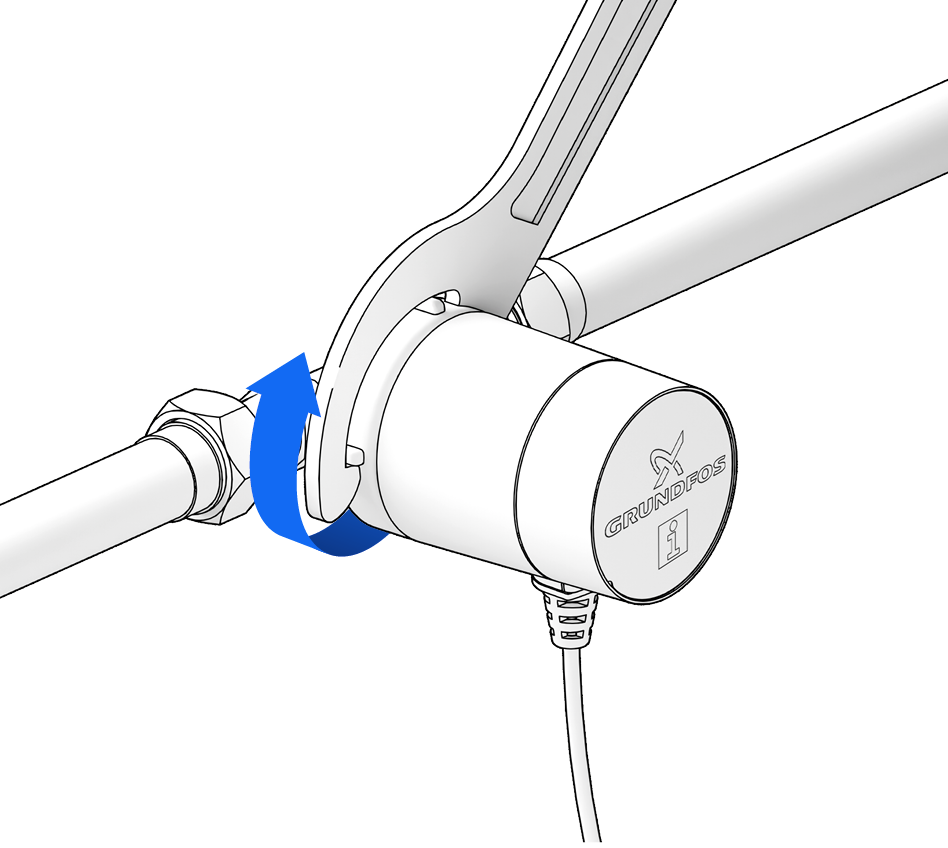

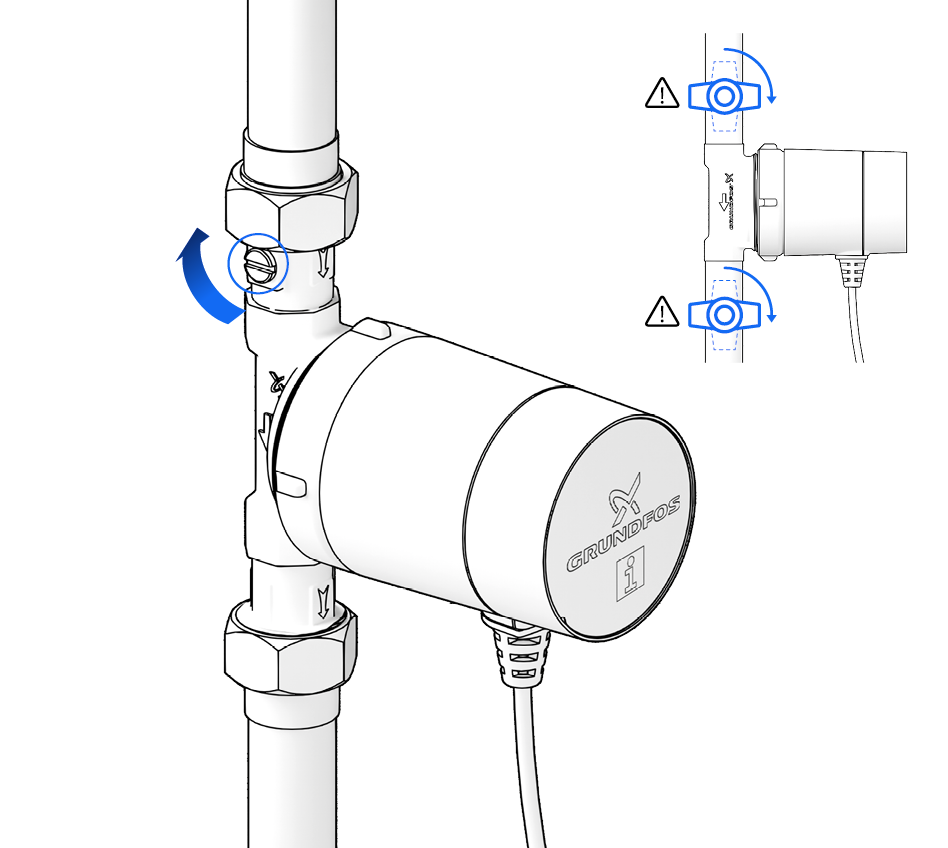

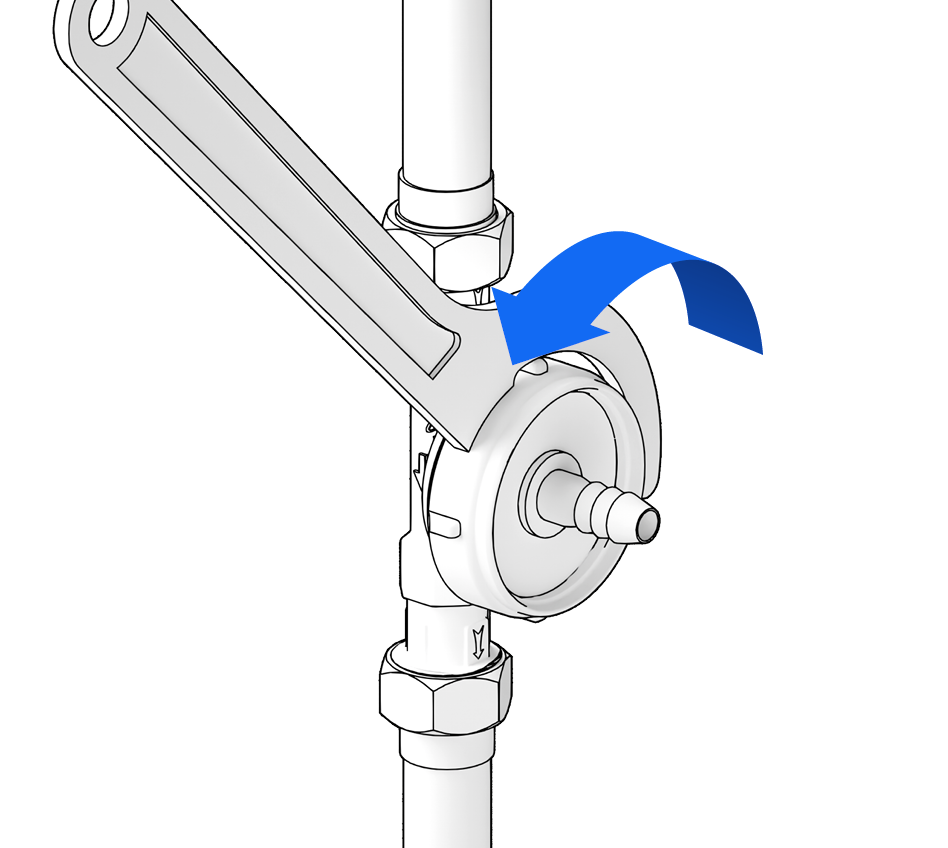

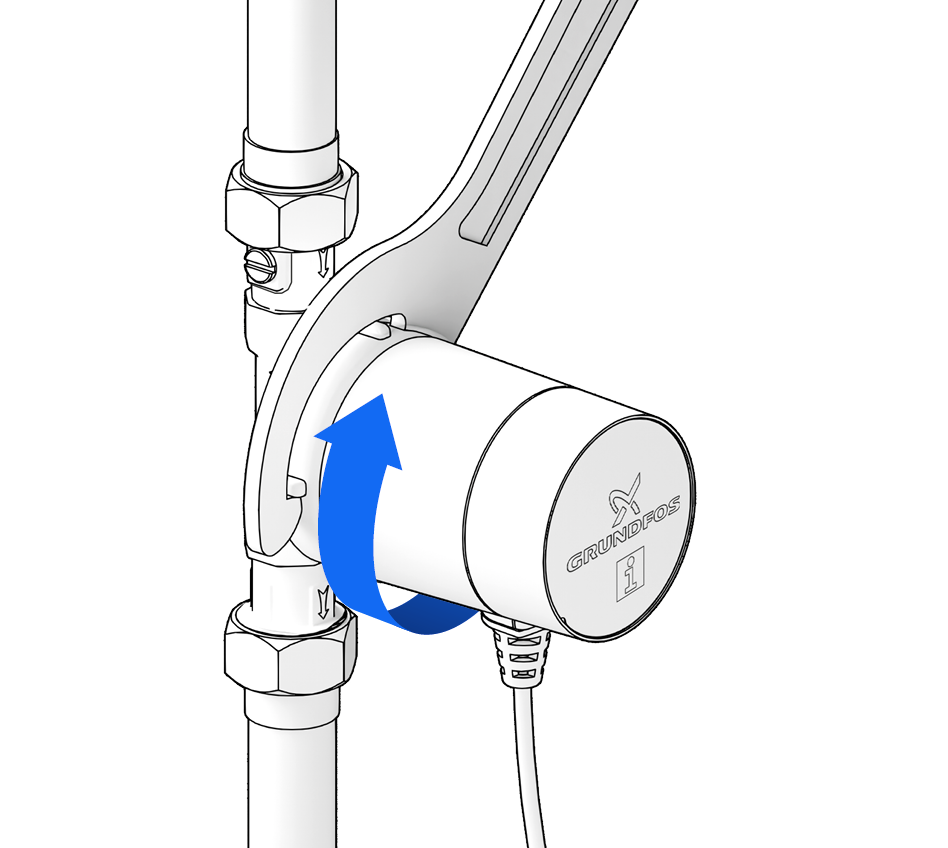

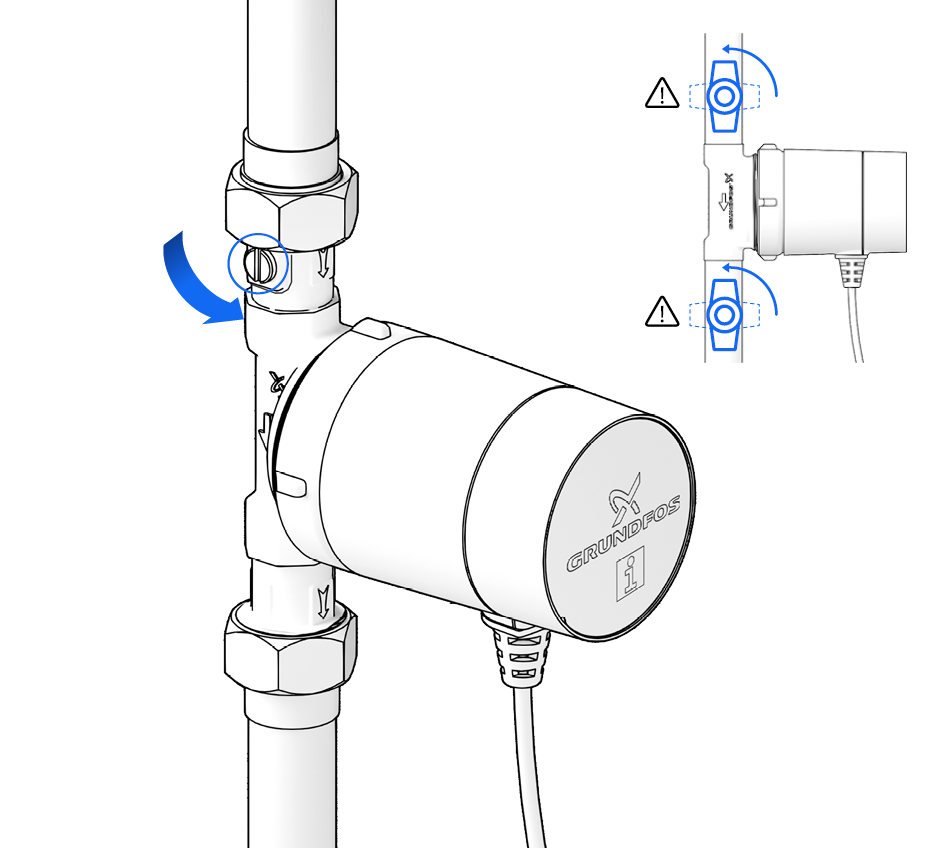

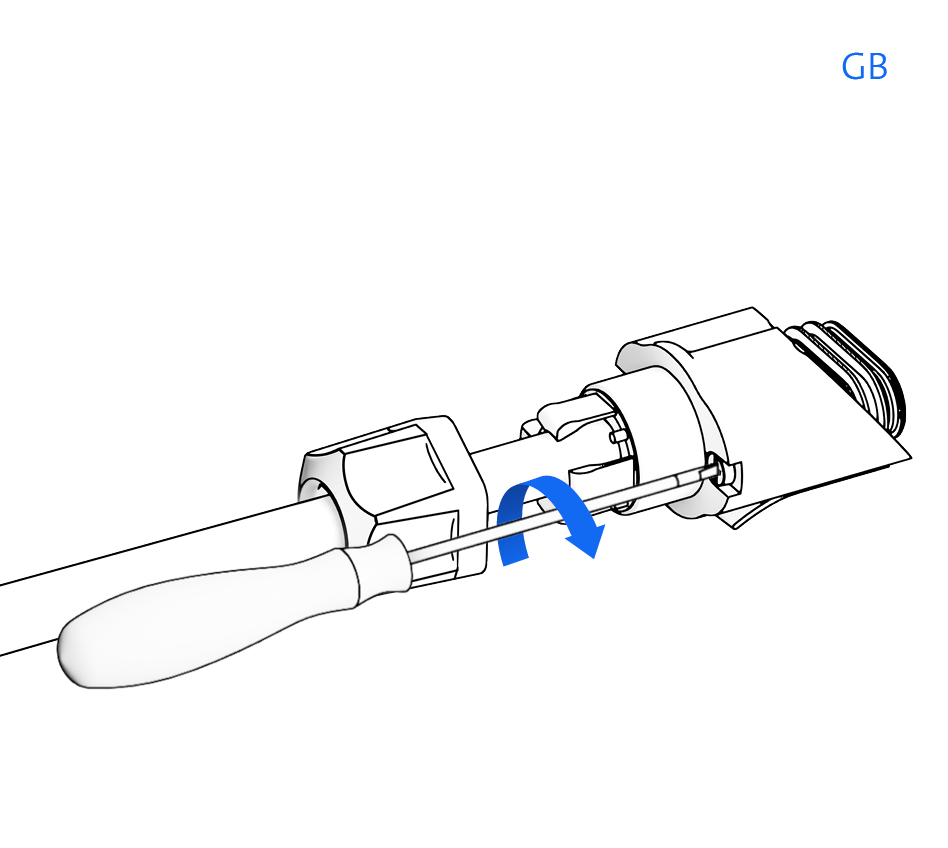

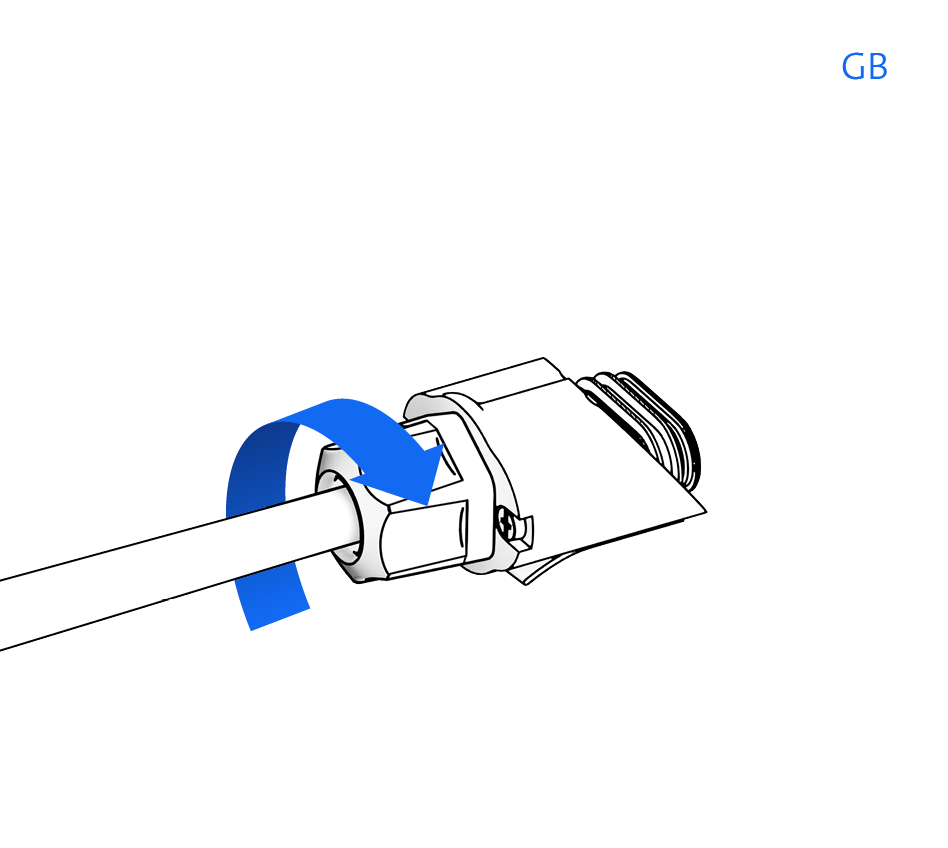

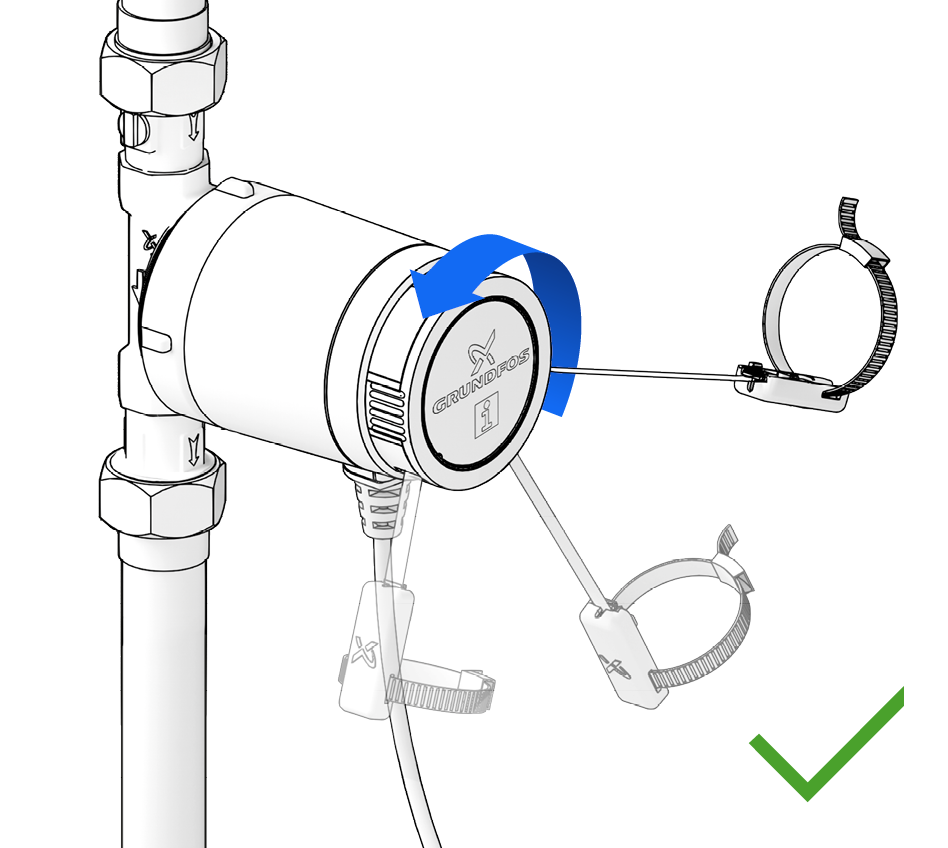

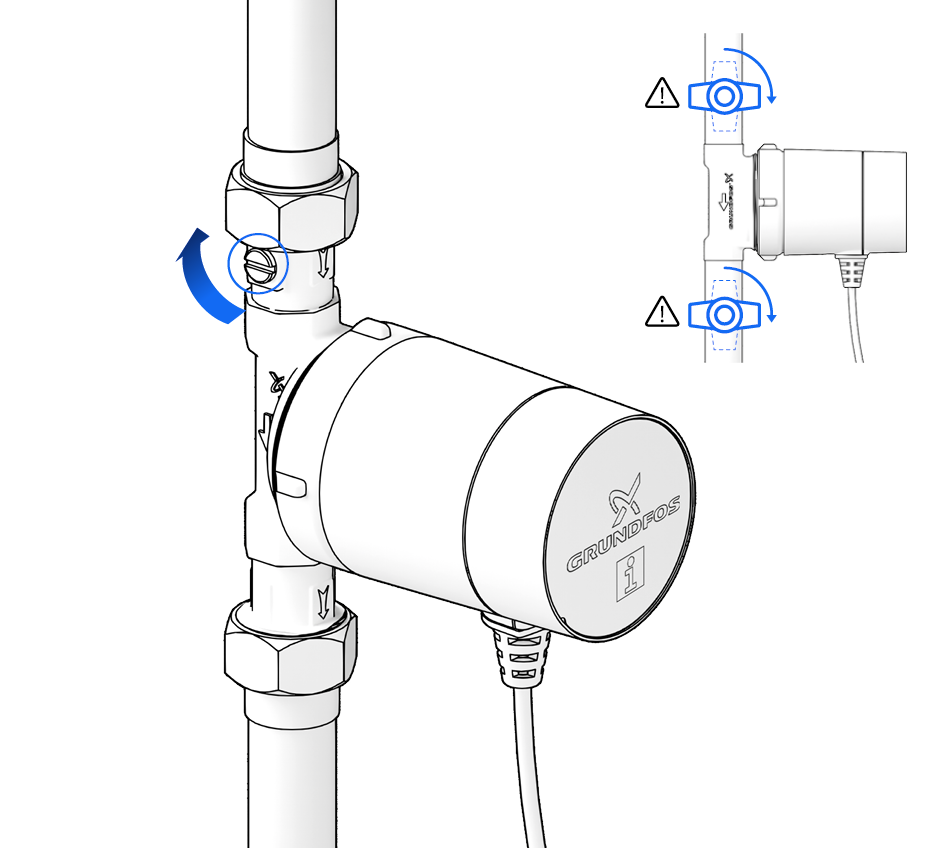

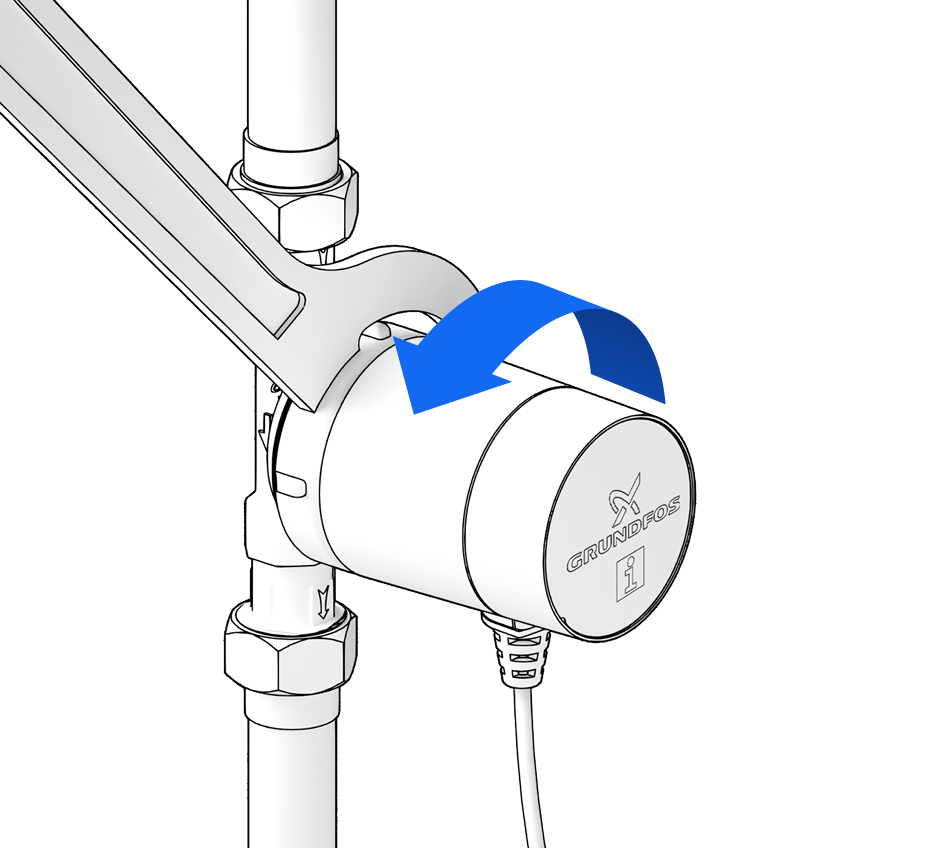

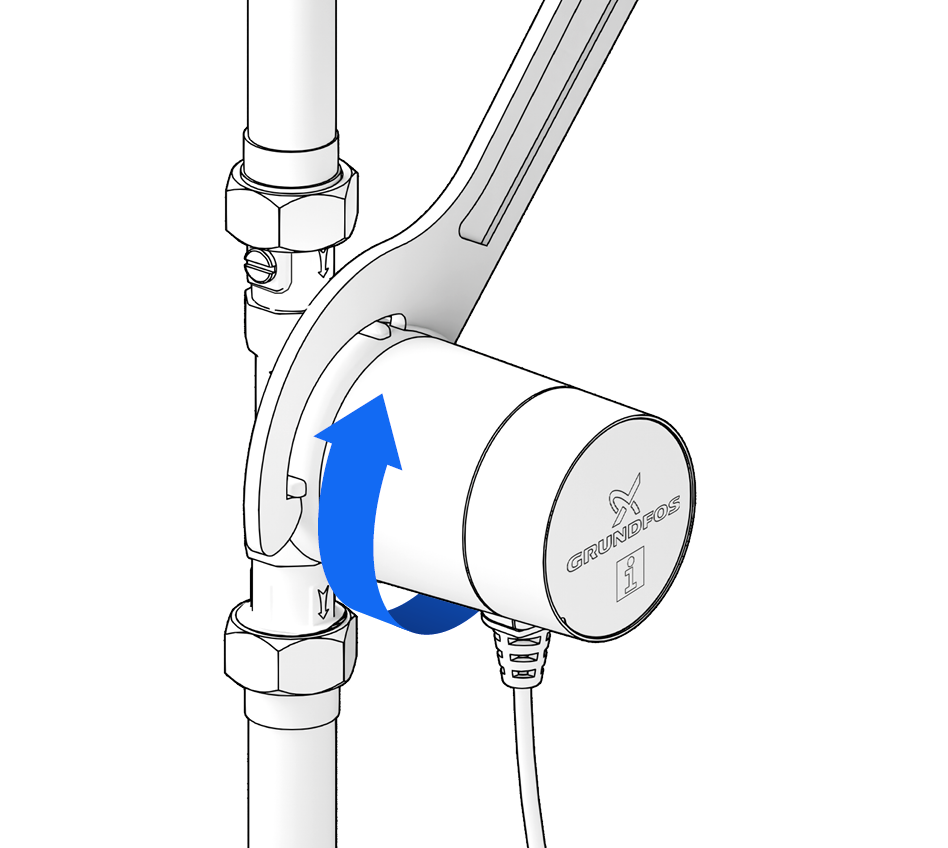

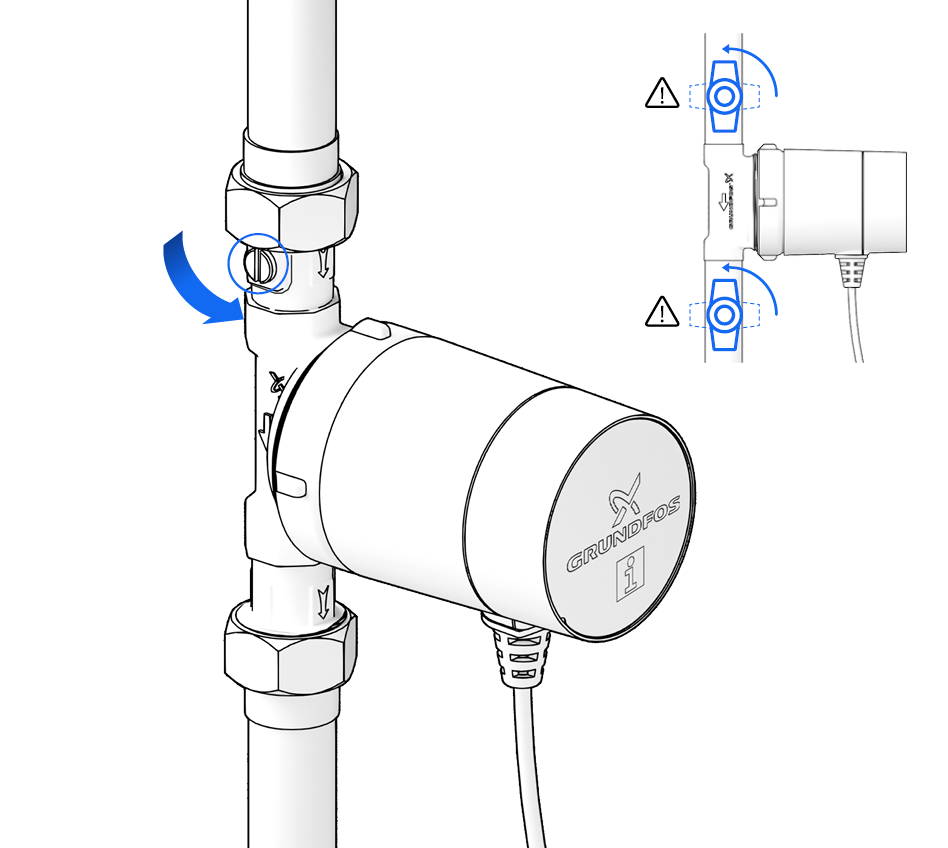

Rotate the pump control panel if necessary so that it is visible (cable exit underneath). To do so, slightly loosen the union nut …

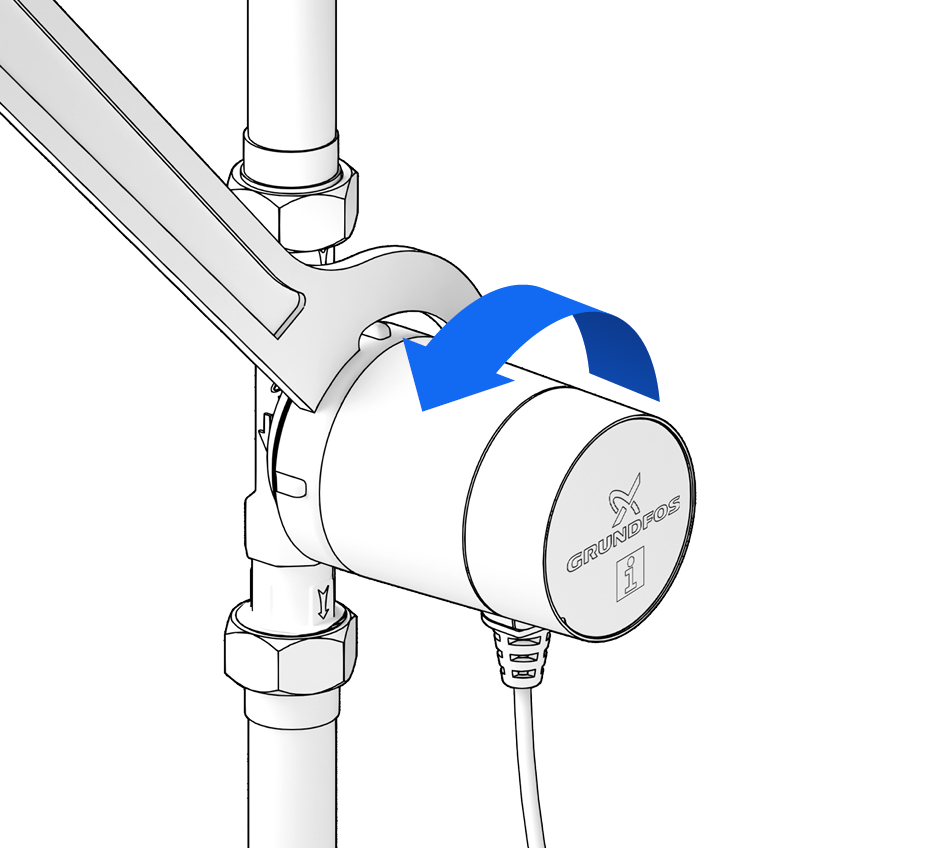

… turn the motor …

… and retighten the union nut

(max. 20 Nm).

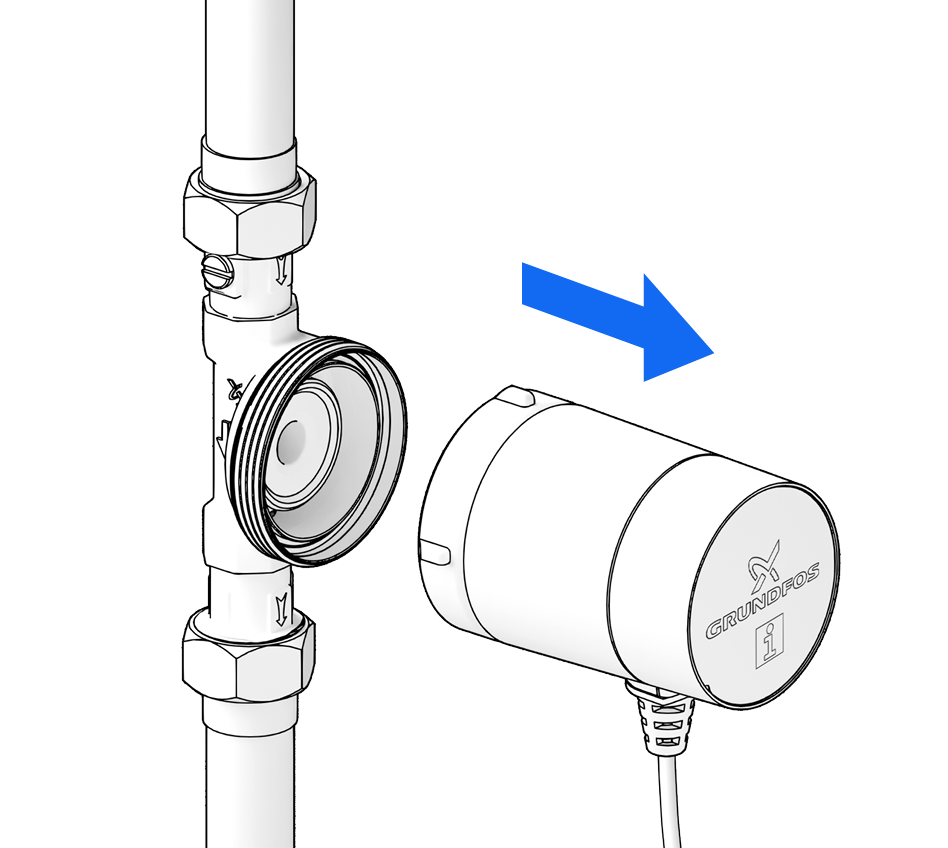

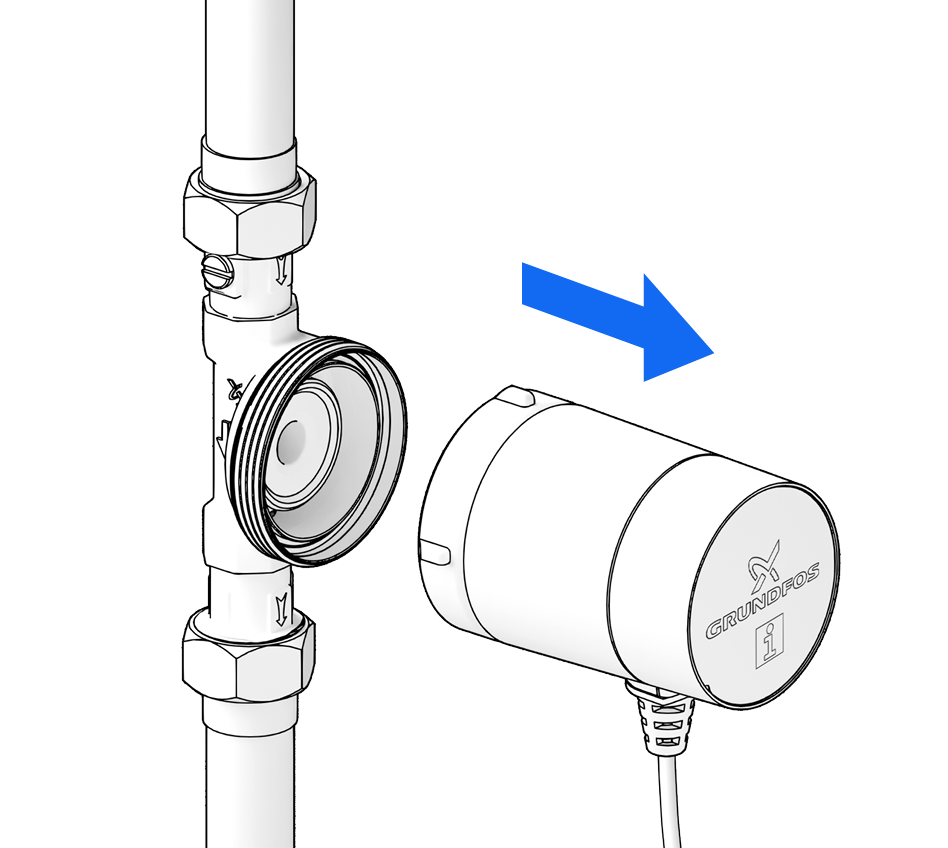

- Fully separating the motor from the pump housing is only necessary for maintenance purposes (see chapters ‘Flushing and Venting’ and ‘Service and Replacement’).

- The pump has dry-running protection. If it runs largely in air, the PCB will repeatedly stop it to protect the rotor bearings. In a fully vented circulation circuit, the pump will run uninterrupted.

CAUTION! Dry-running will damage the bearings!

- Flush the pipework thoroughly with water and vent it.

DANGER! Pressurised system!

- Before working on the motor or pump connections, close the shut-off valves.

WARNING! Risk of scalding due to hot water!

- Avoid direct contact with escaping hot water.

- The pump housing can similarly reach a high temperature due to the hot medium being pumped.

- If no venting valve (fill & drain valve) is present, the system must be vented through the pump housing.

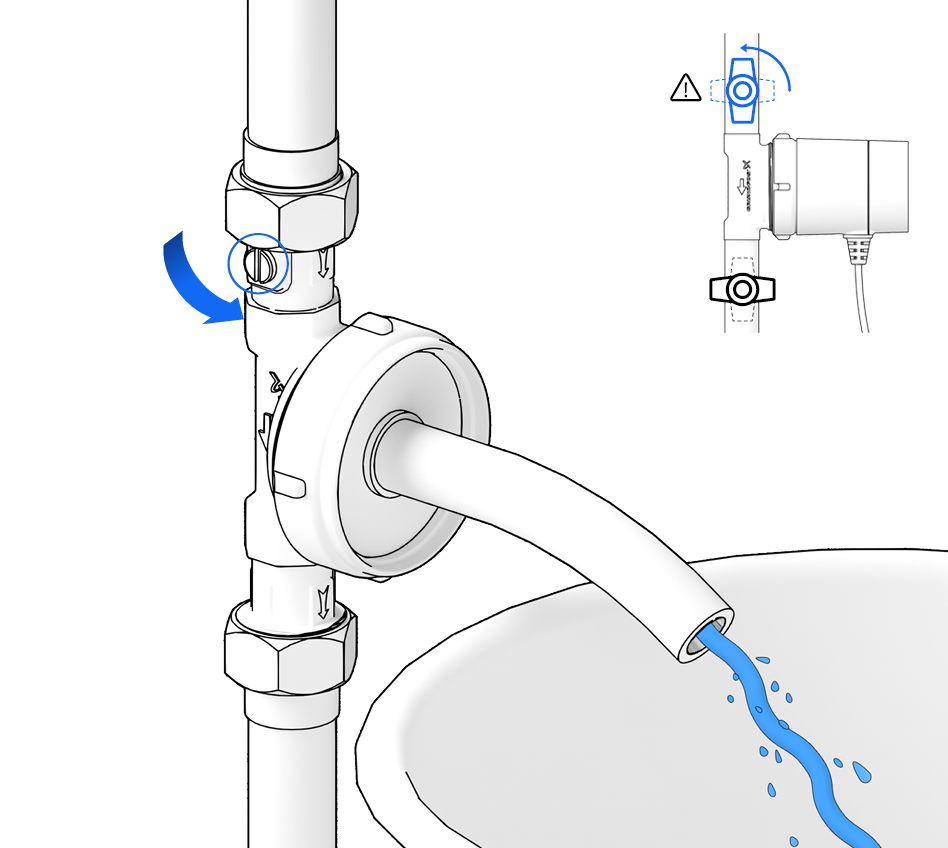

To vent, first close the shut-off valves.

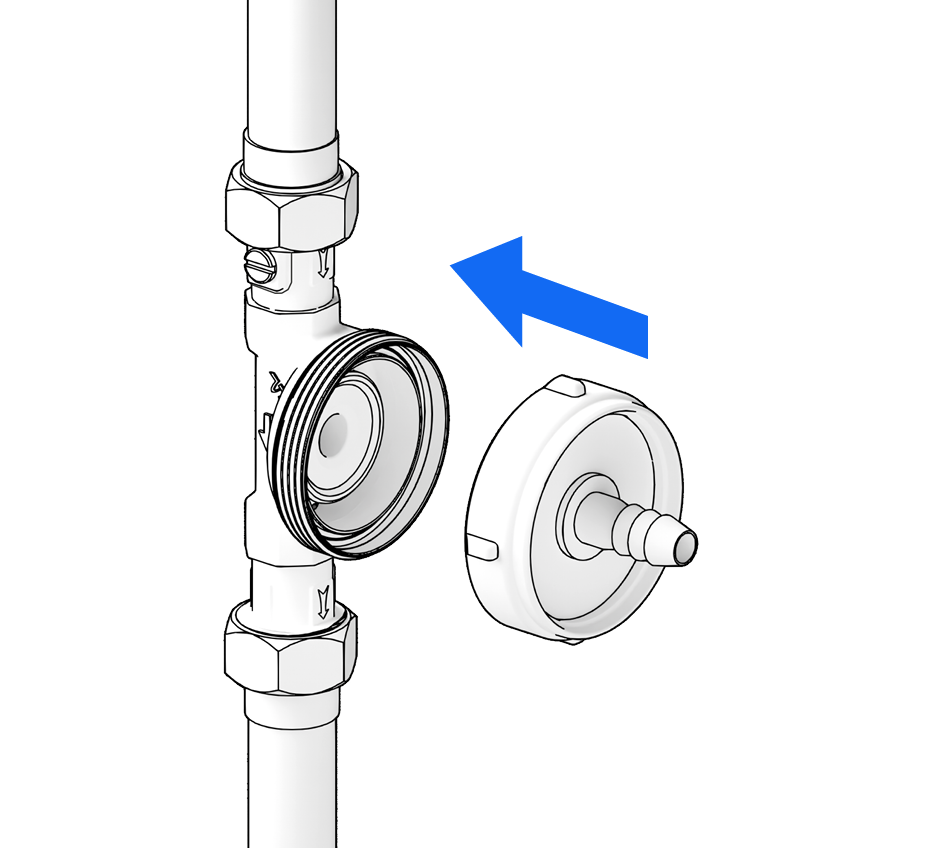

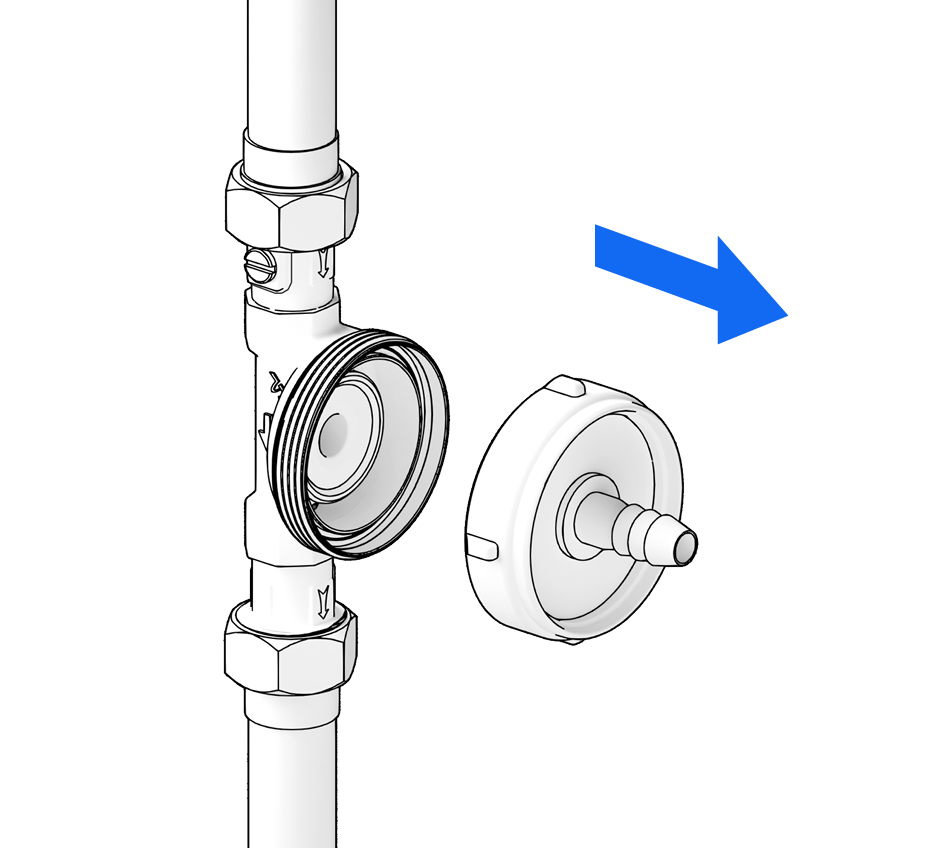

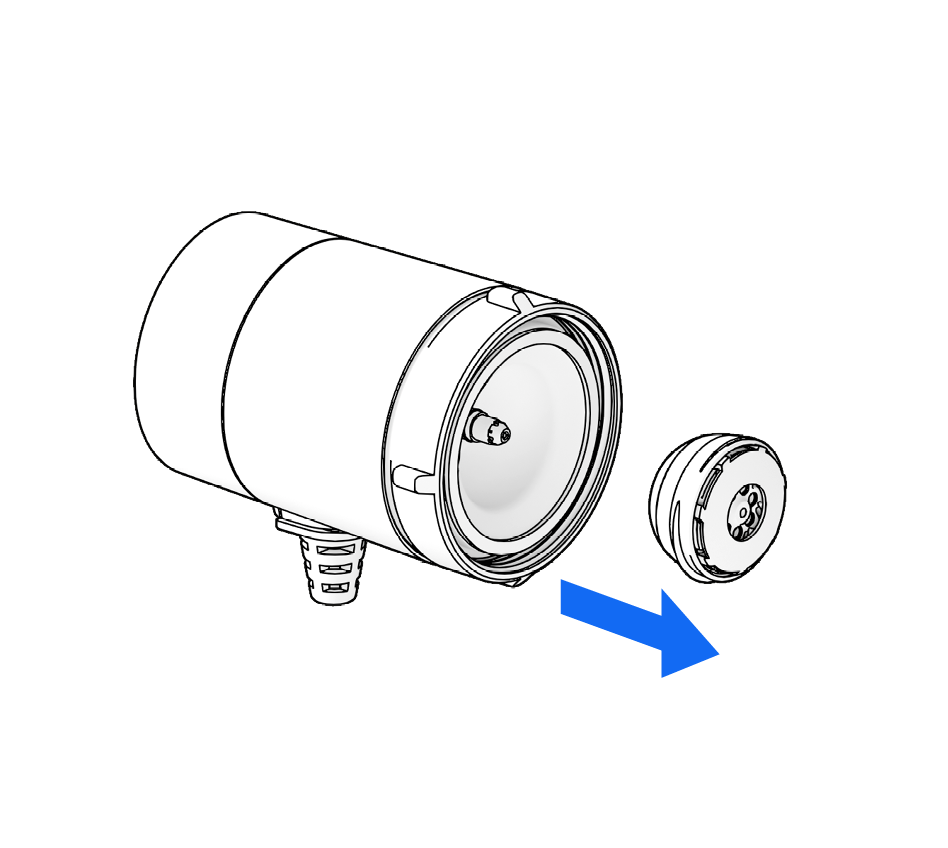

Unscrew the motor from the pump housing …

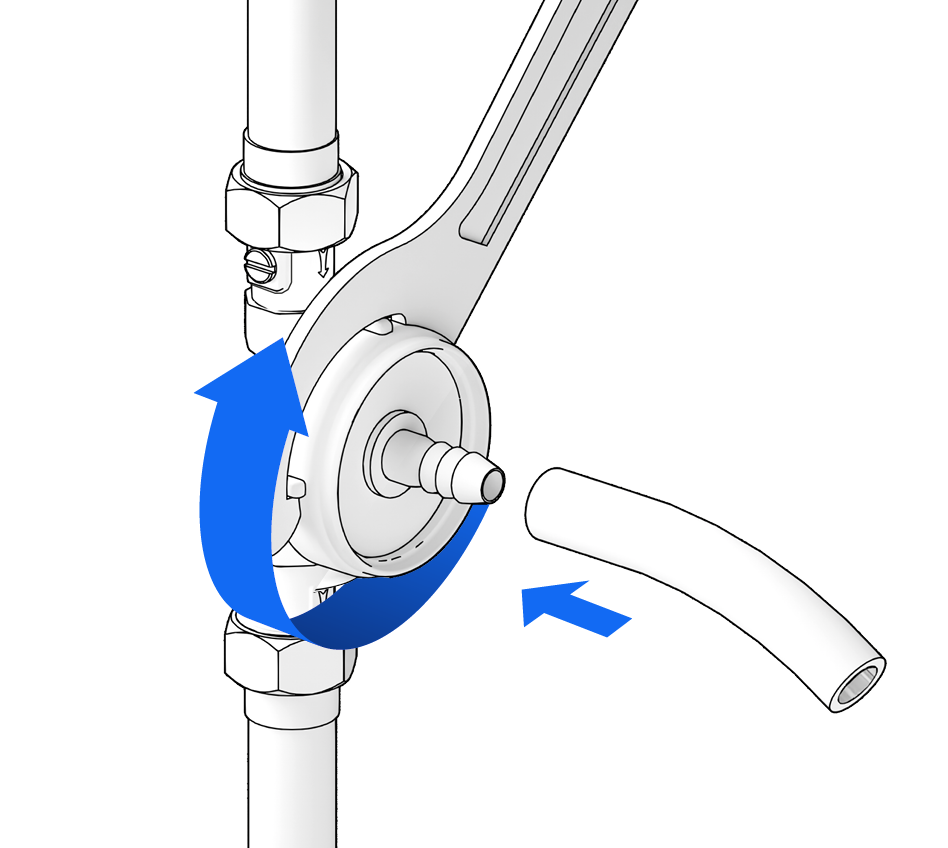

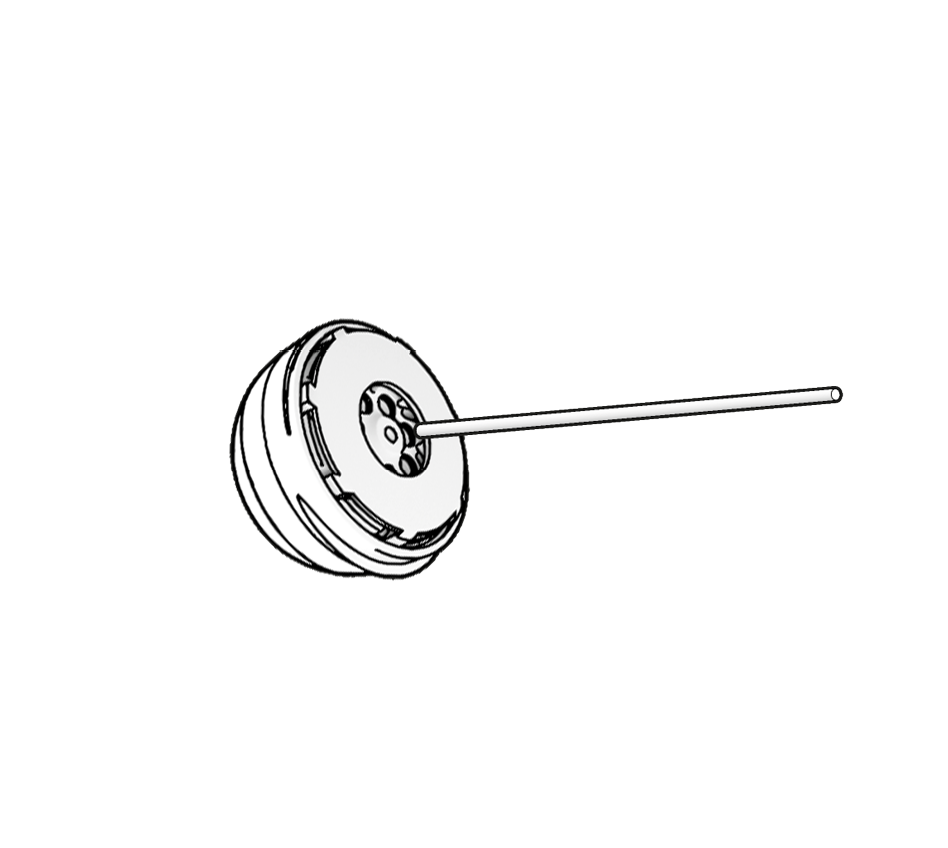

… and screw the venting flange onto the motor (max. 20 Nm).

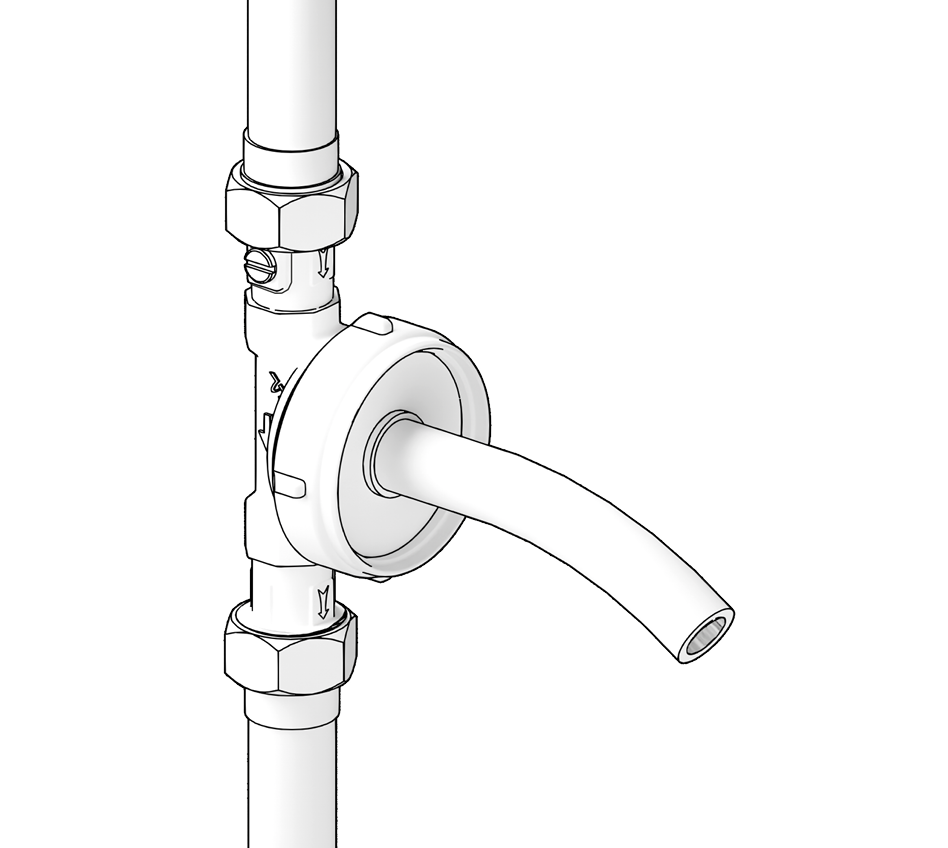

Open the shut-off valve upstream of the pump again and allow water to escape through the venting flange until the pipework is free of air.

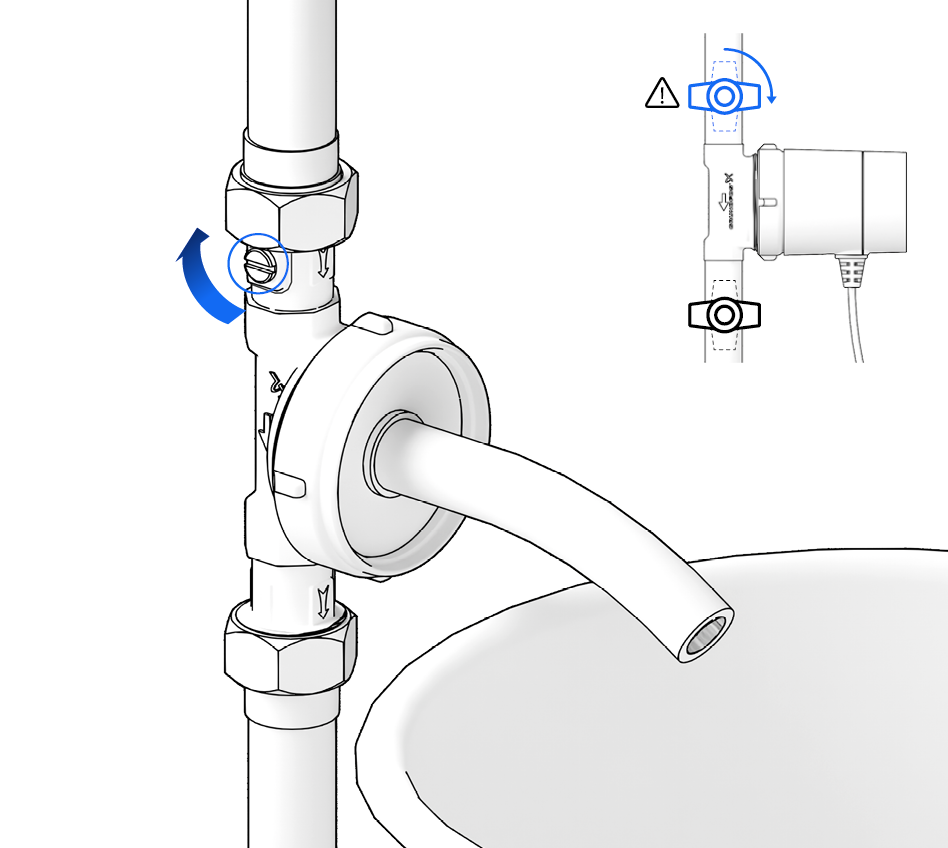

Close the shut-off valve upstream of the pump …

… unscrew the venting flange from the pump …

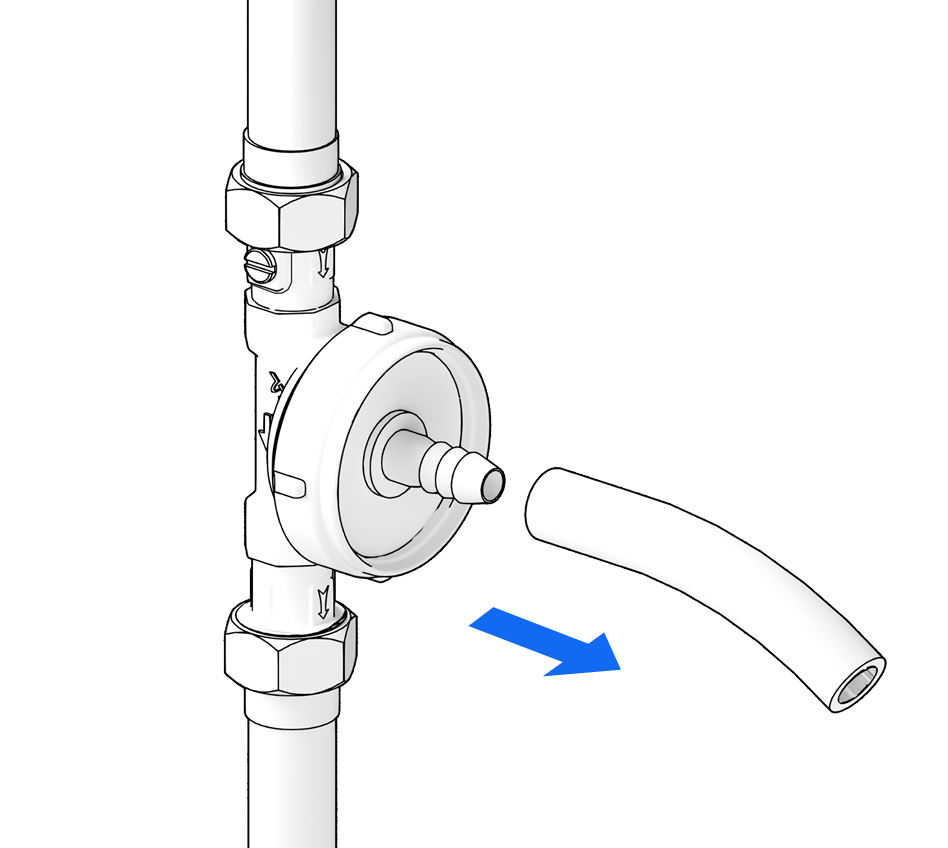

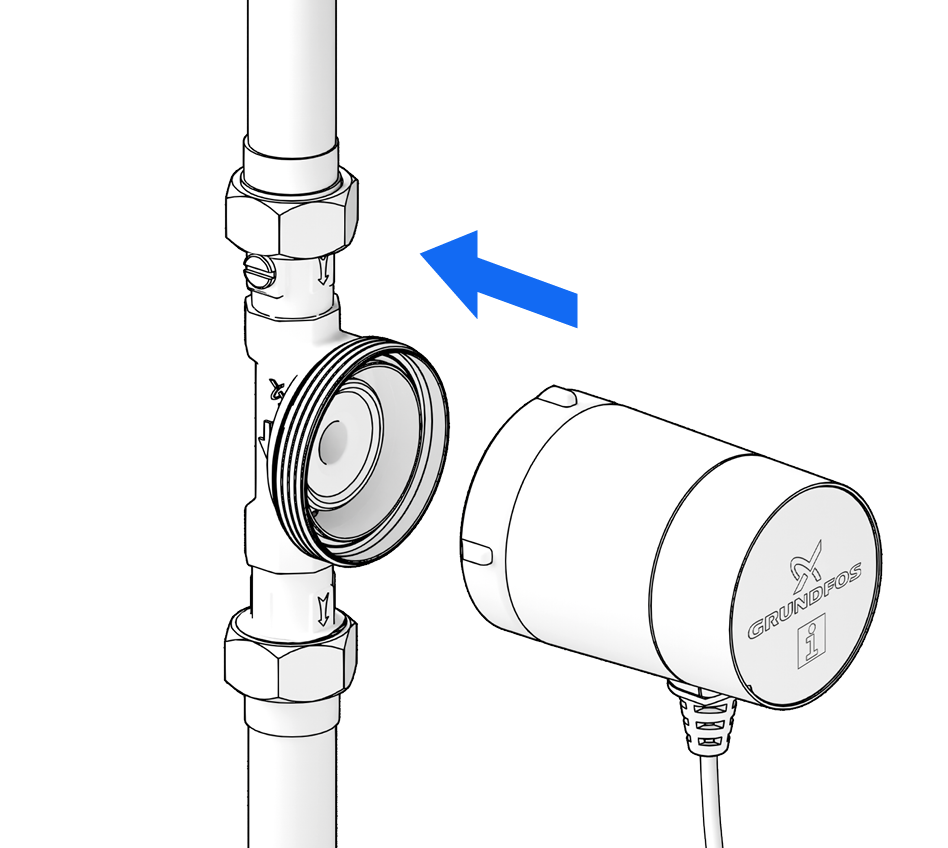

… and reattach the motor to the pump housing.

Retighten the union nut

(max. 20 Nm).

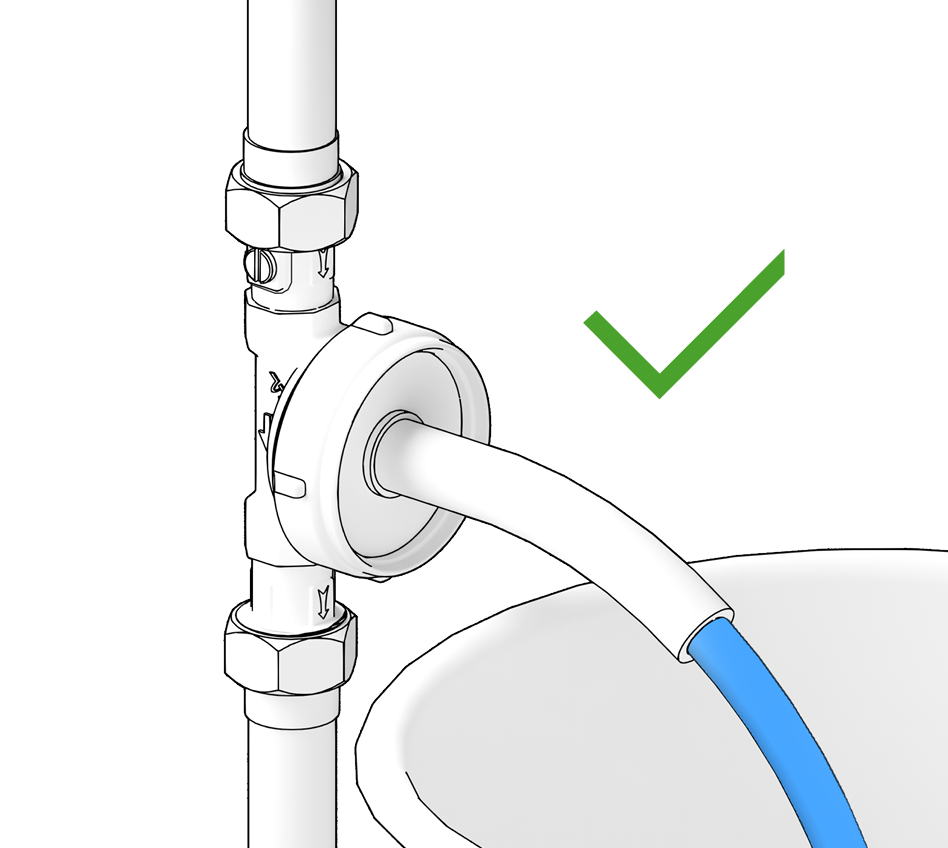

Slowly open the shut-off valves again.

- The pump is driven by a DC motor.

- The transformer for AC operation is built into the motor cap.

- Line cord is integrated in the pump.

DANGER! Electric shock can kill!

- Work on the electrics must be carried out only by authorised contractors.

- Disconnect the pump from the power supply and secure against reconnection.

- Check that no voltage is present.

WARNING! Risk of fire due to electrical ignition!

- Ensure that the pump is connected only to the power supply specified on the nameplate.

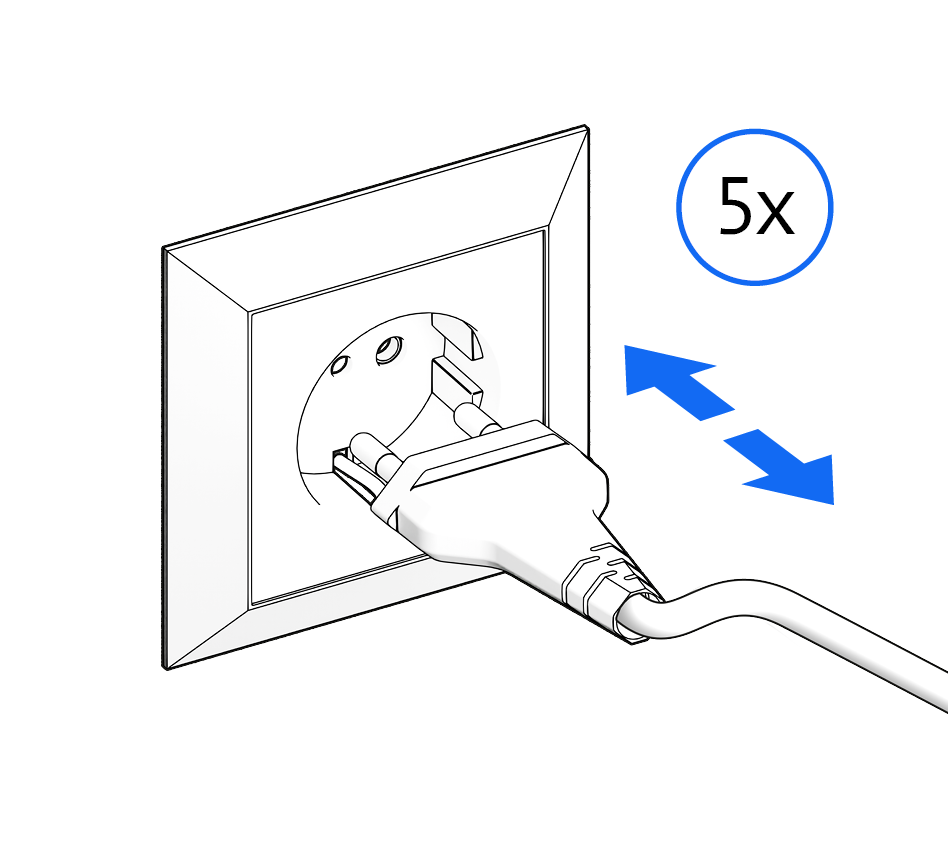

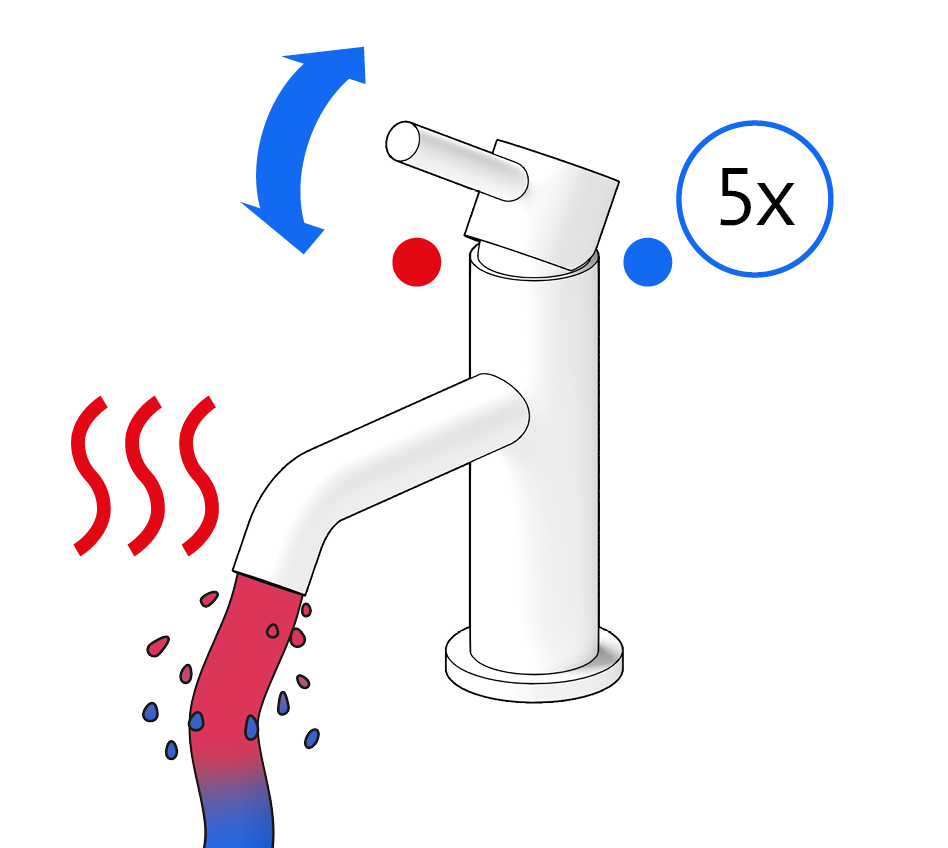

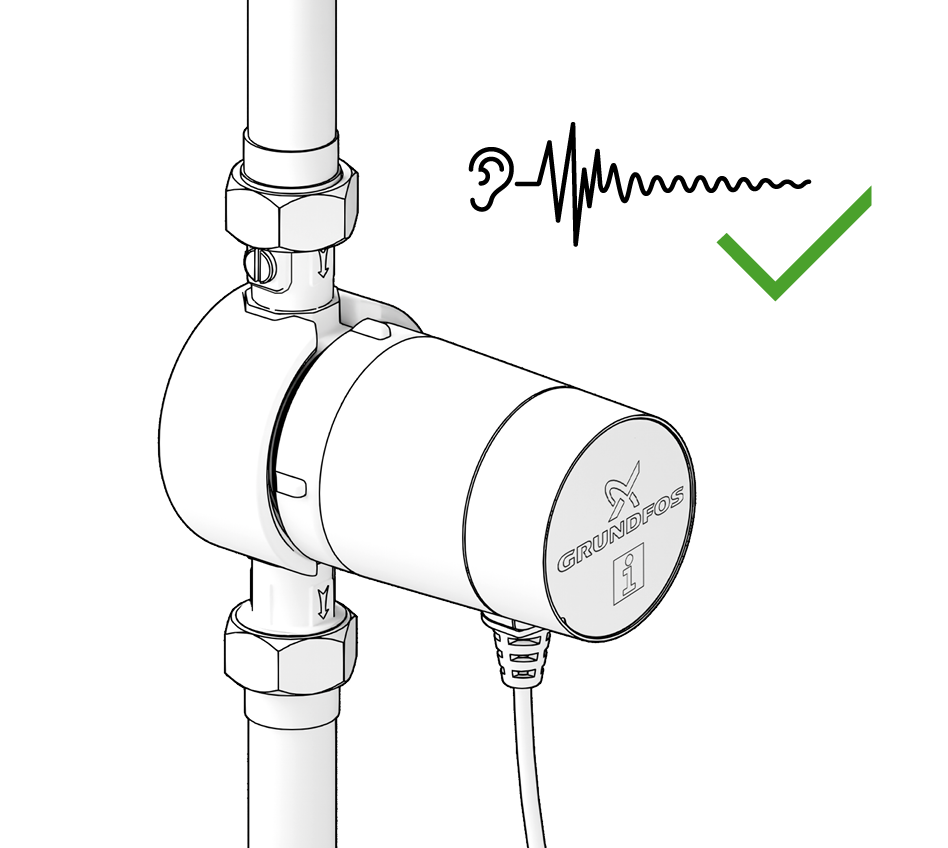

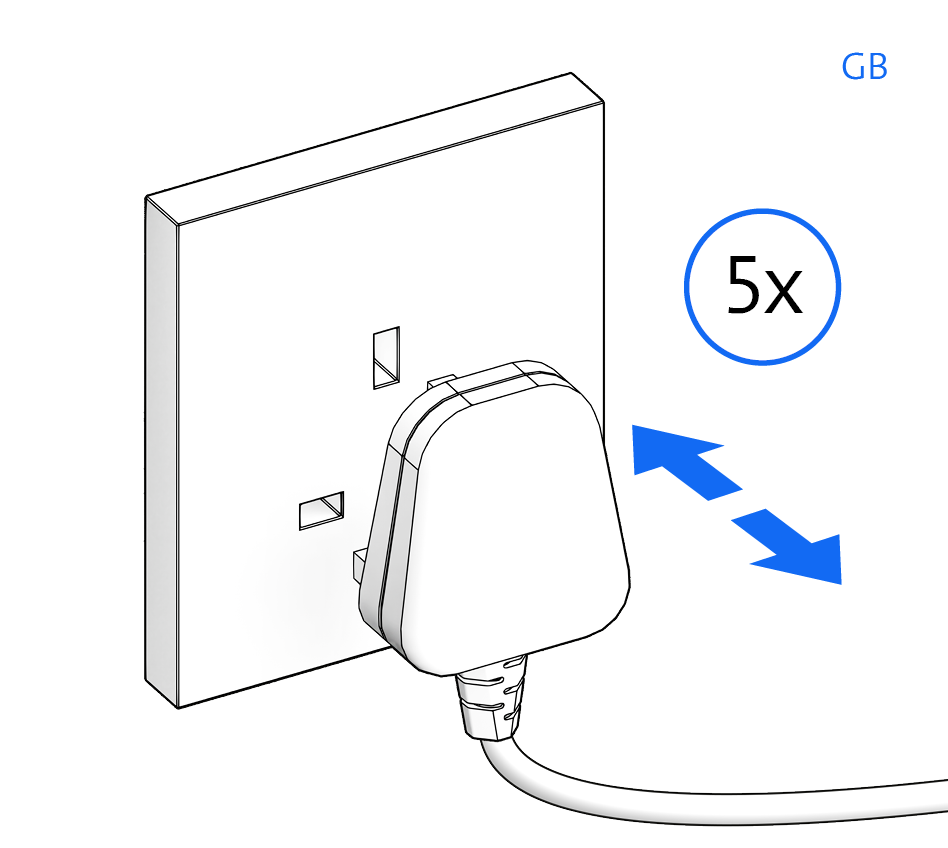

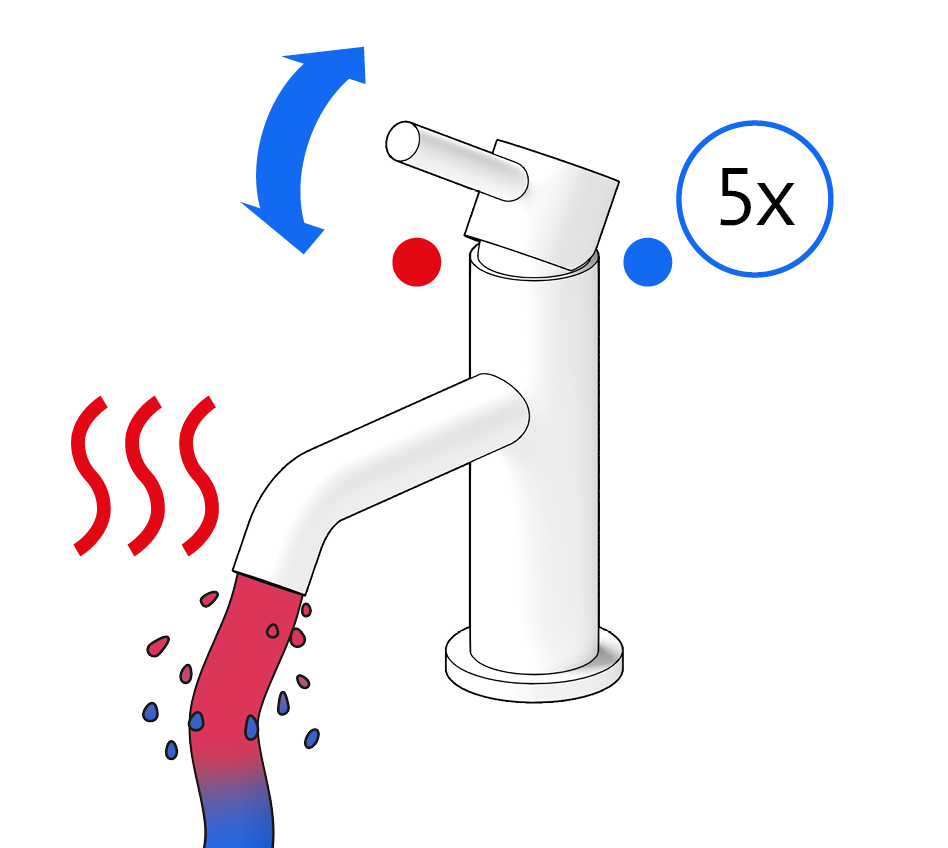

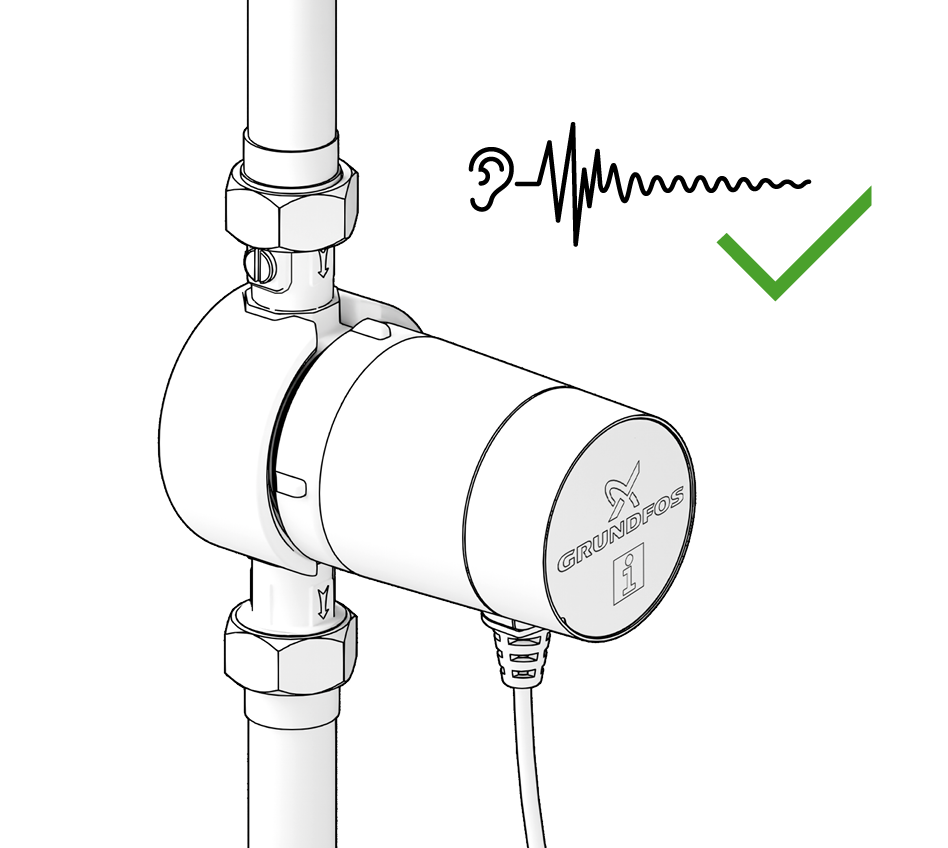

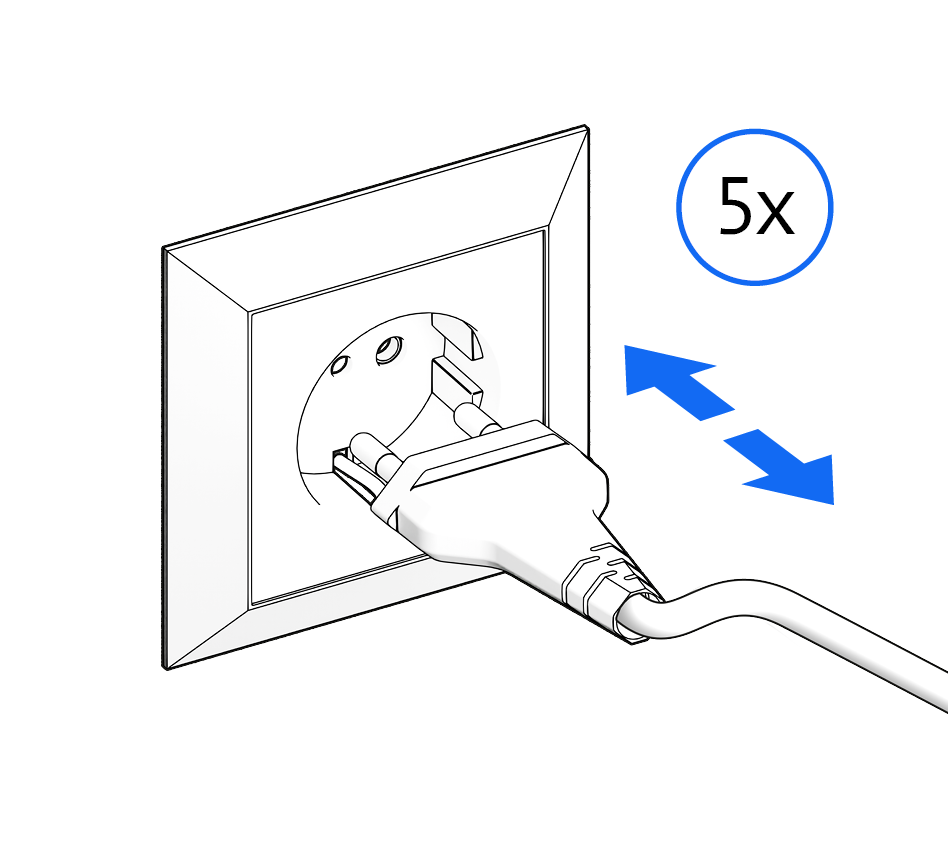

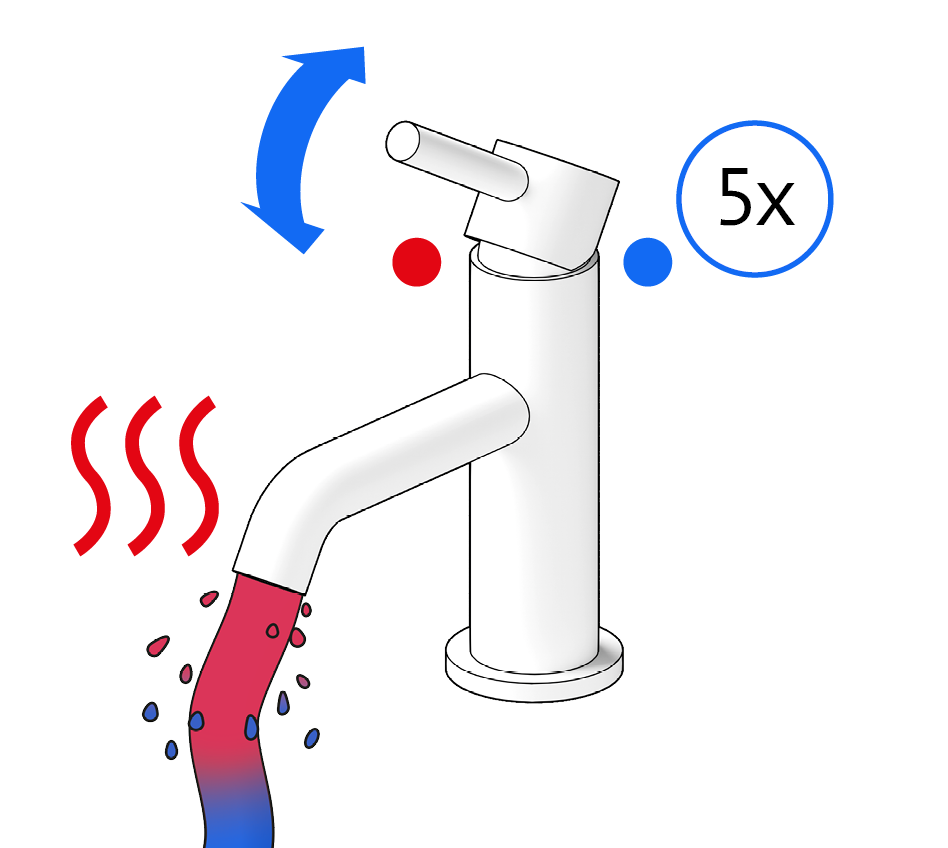

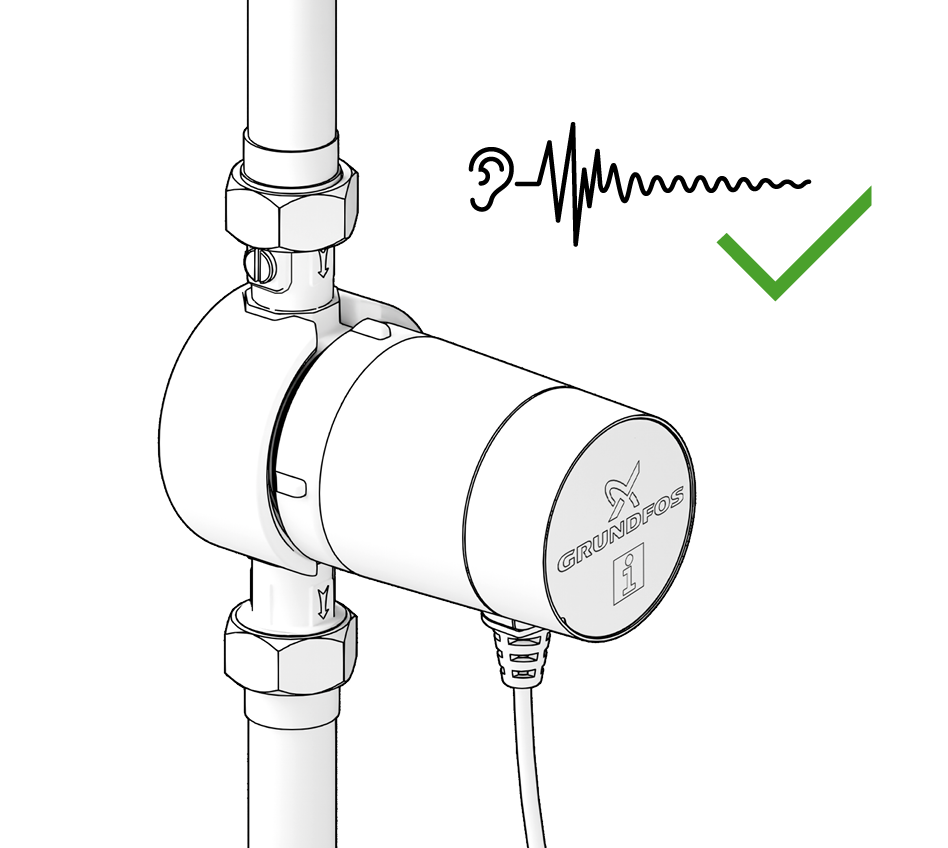

To vent any remaining air, switch the pump on and off several times …

… and open the DHW tap several times …

… until the pump runs quietly.

- The pump is driven by a DC motor.

- The transformer for AC operation is built into the motor cap.

- Line cord is integrated in the pump.

DANGER! Electric shock can kill!

- Work on the electrics must be carried out only by authorised contractors.

- Disconnect the pump from the power supply and secure against reconnection.

- Check that no voltage is present.

WARNING! Risk of fire due to electrical ignition!

- Ensure that the pump is connected only to the power supply specified on the nameplate.

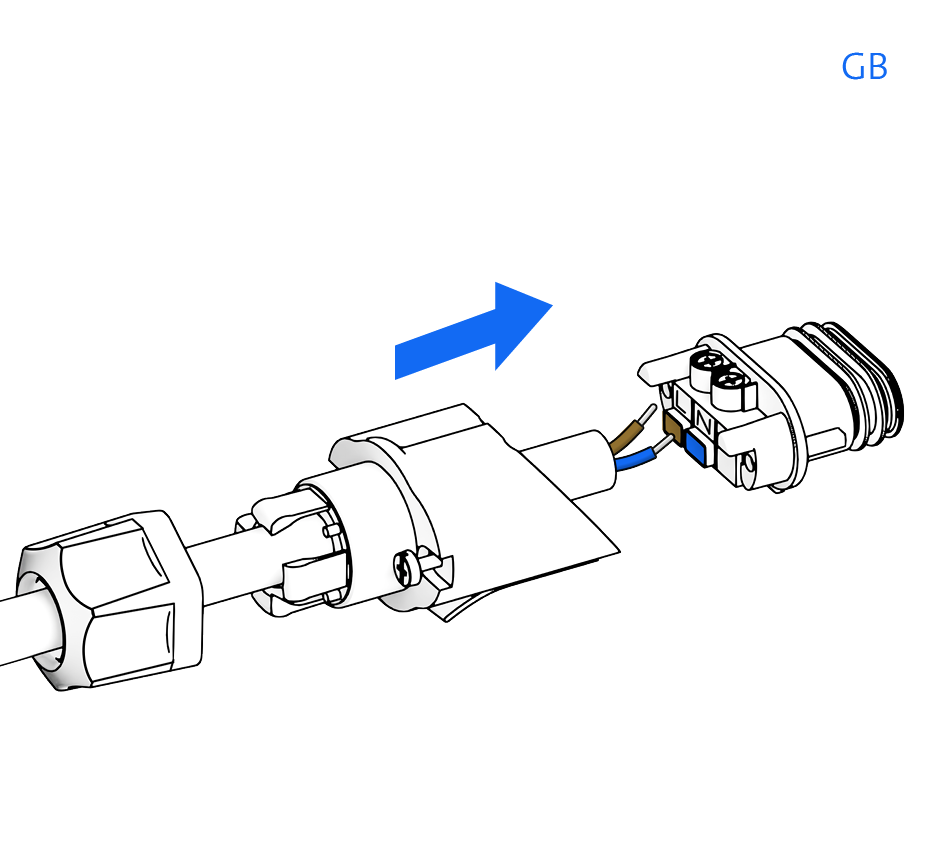

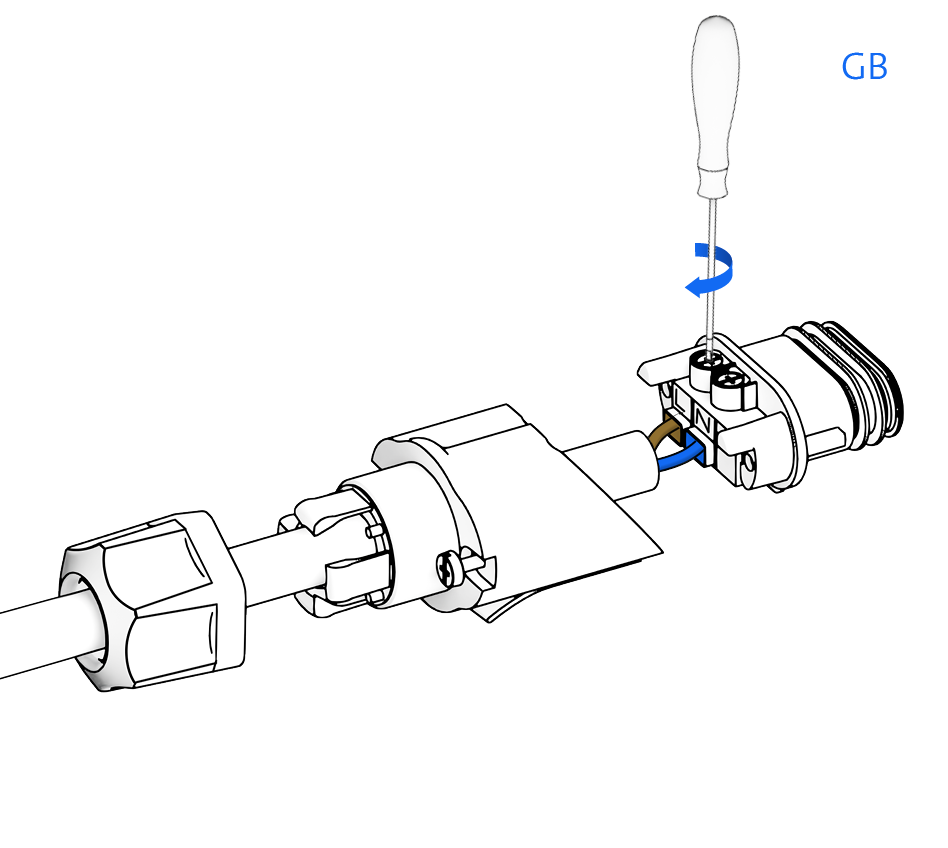

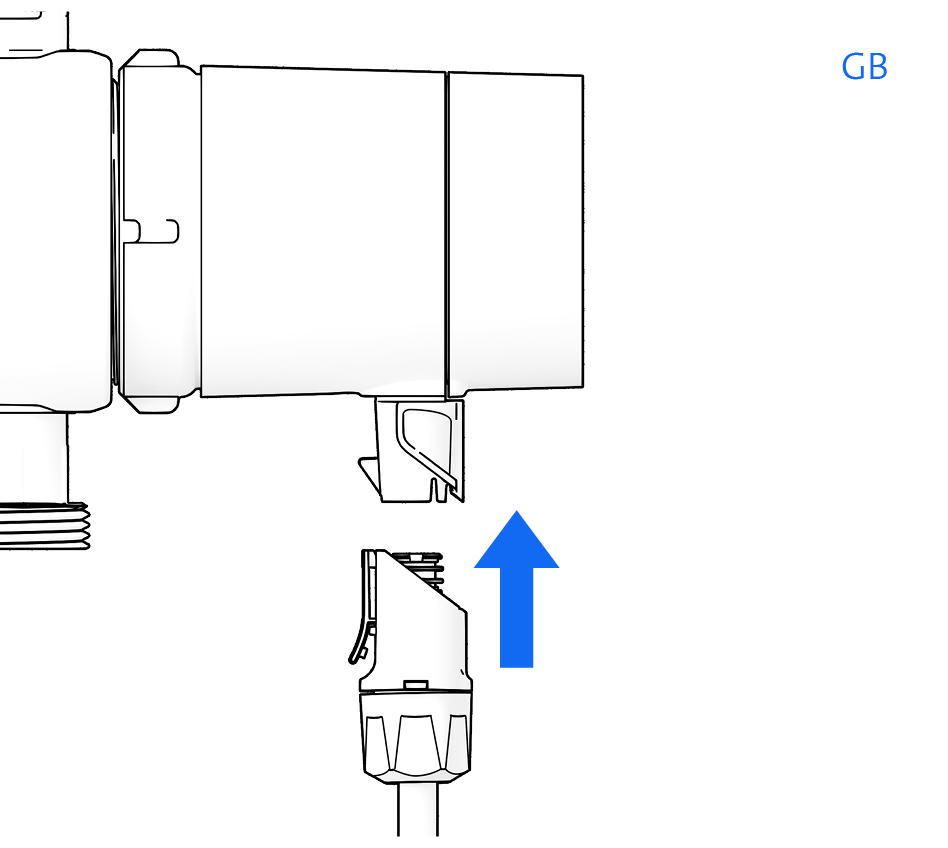

The cable and mains plug must be purchased separately.

Round cable diameter 5-10 mm

- Wire cross-section 1mm2

- Strip 8.5-10 mm of insulator from the ends of the wires.

- Twist the wire ends; do not use wire-end sleeves or tinned ends

No ground connection needed; the pump is double insulated.

To vent any remaining air, switch the pump on and off several times …

… and open the DHW tap several times …

… until the pump runs quietly.

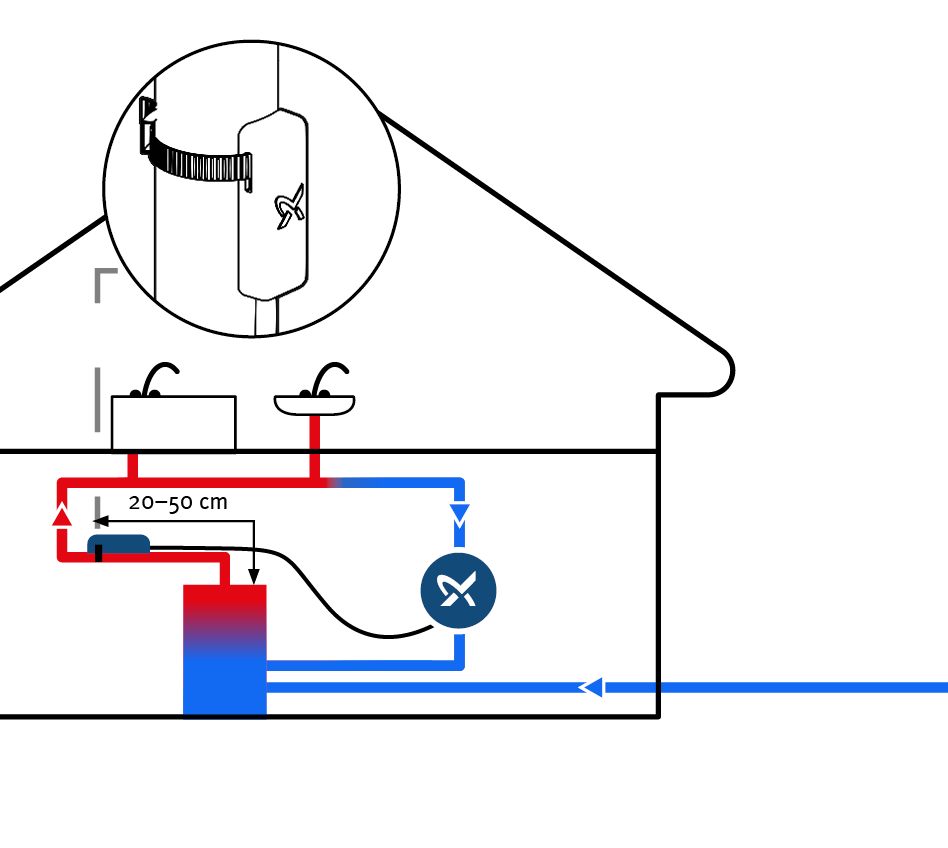

- The external sensor should be installed on the DHW flow (regardless of

the type of DHW heat source). The optimum distance from the external

sensor to the DHW heater is 20–30 cm (for a plastic/composite pipe) or

50 cm (for a metal pipe). If the flow line exits vertically from the DHW

heater, fit a U-bend upstream of the sensor installation location.

Otherwise DHW draw-off will not be detected as the temperature change

will be too small.

- If a mixer tap is installed, install the external sensor at an appropriate distance downstream of the mixer tap.

- Install the external sensor only on a straight section of pipe (without bends, corrugations, taps or tee-joints).

- The DHW heating system must deliver a constant temperature level of at

least 120 °F (48 °C) (except during night setback). Otherwise, the

required level of DHW convenience cannot be guaranteed. - Branched pipework systems (multiple-circuit systems) must be

hydraulically balanced by means of regulating valves in the return

lines. Otherwise, the level of convenience may be adversely affected as

the pump may switch off too early.

The pump requires a permanent power supply.

Do not connect the pump to an additional controller or timer.

If hot water is not available directly after opening a tap, turn the tap off again and wait for circulation to start.

DO NOT PULL

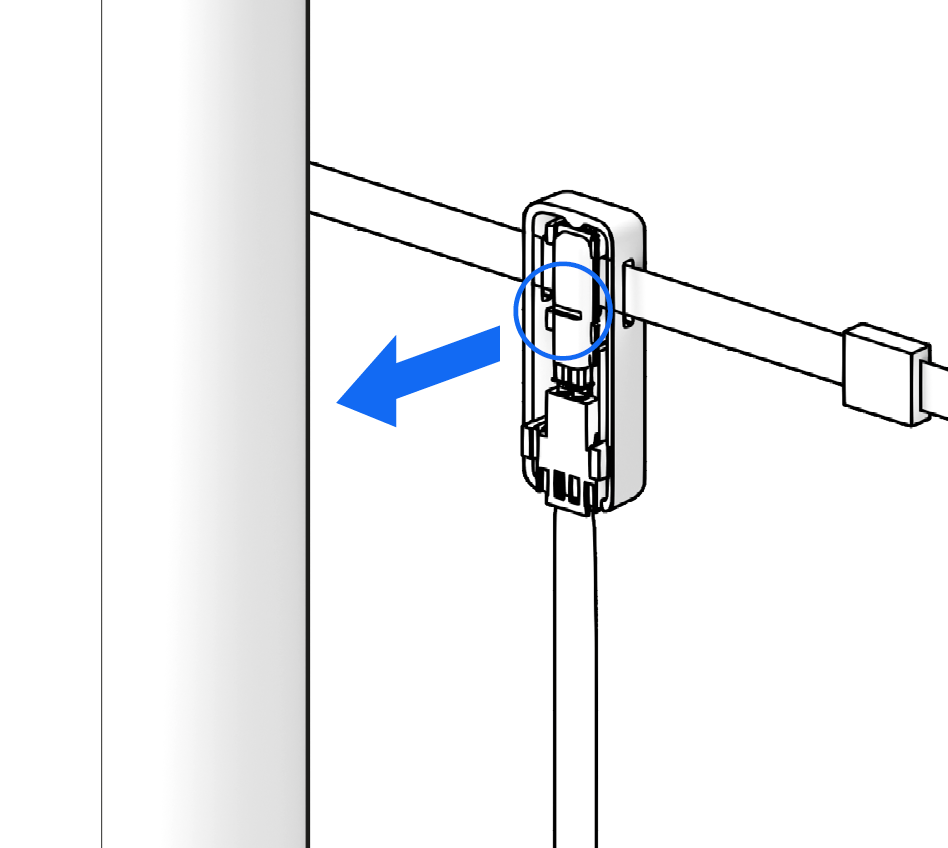

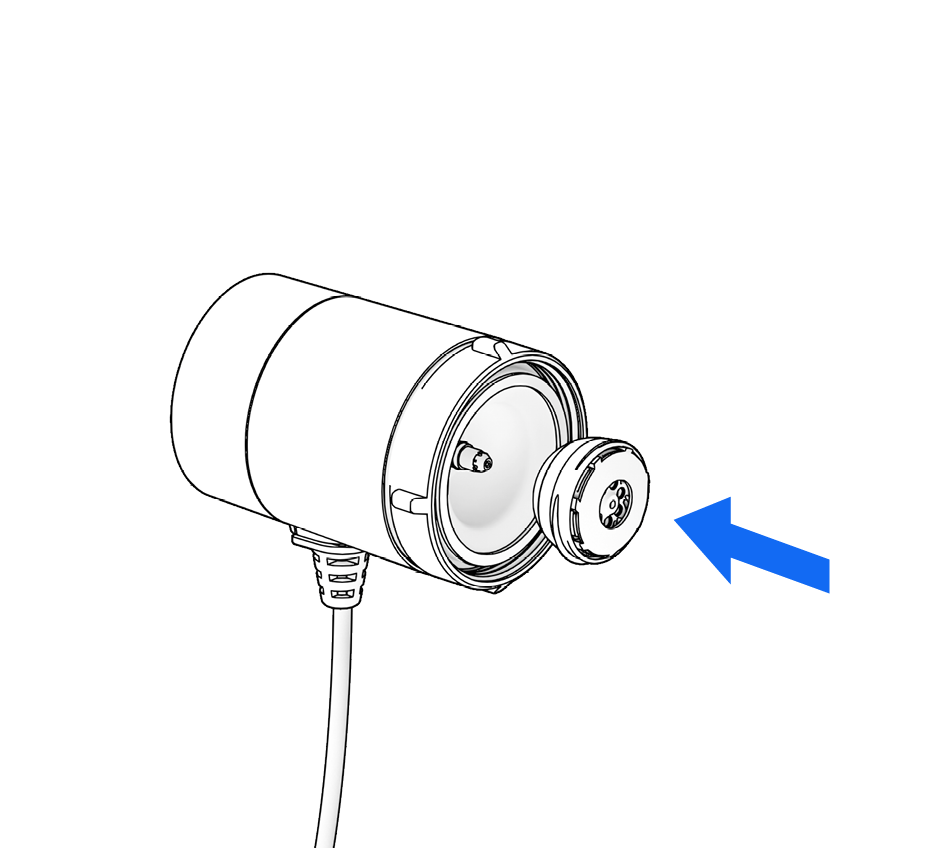

- External sensor is already built in and connected with the pump.

- Make sure you don’t damage the sensor cable.

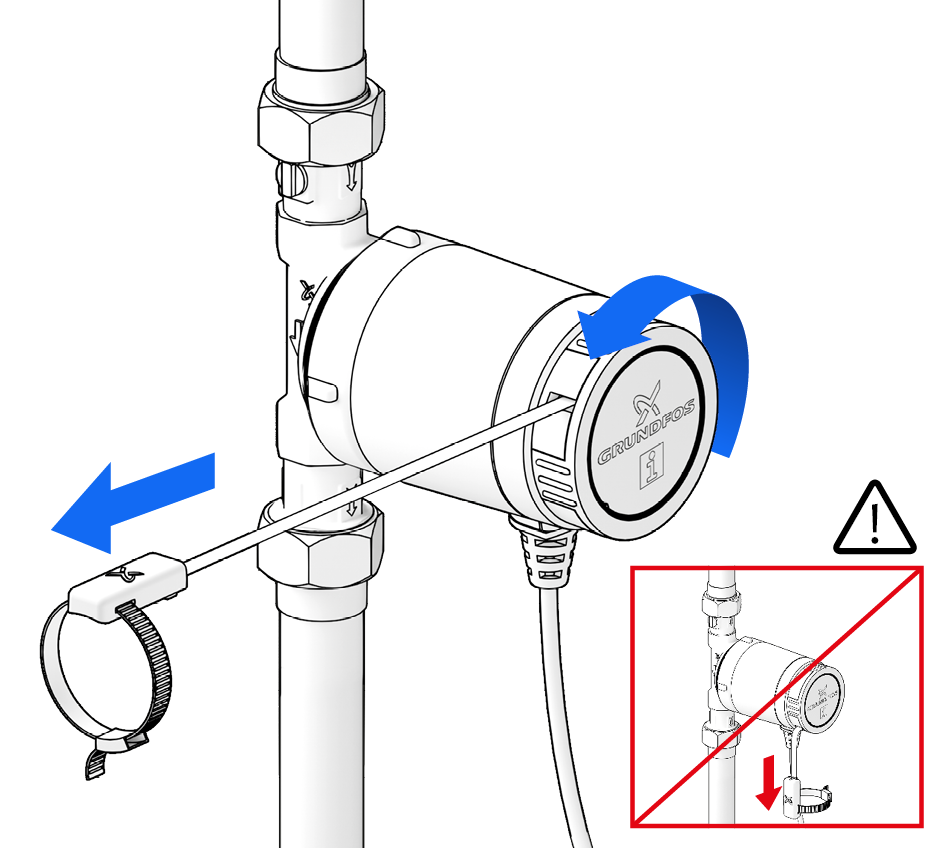

Gently unwind the sensor cable counterclockwise to desired length. The maximum length is 8ft (2.5m).

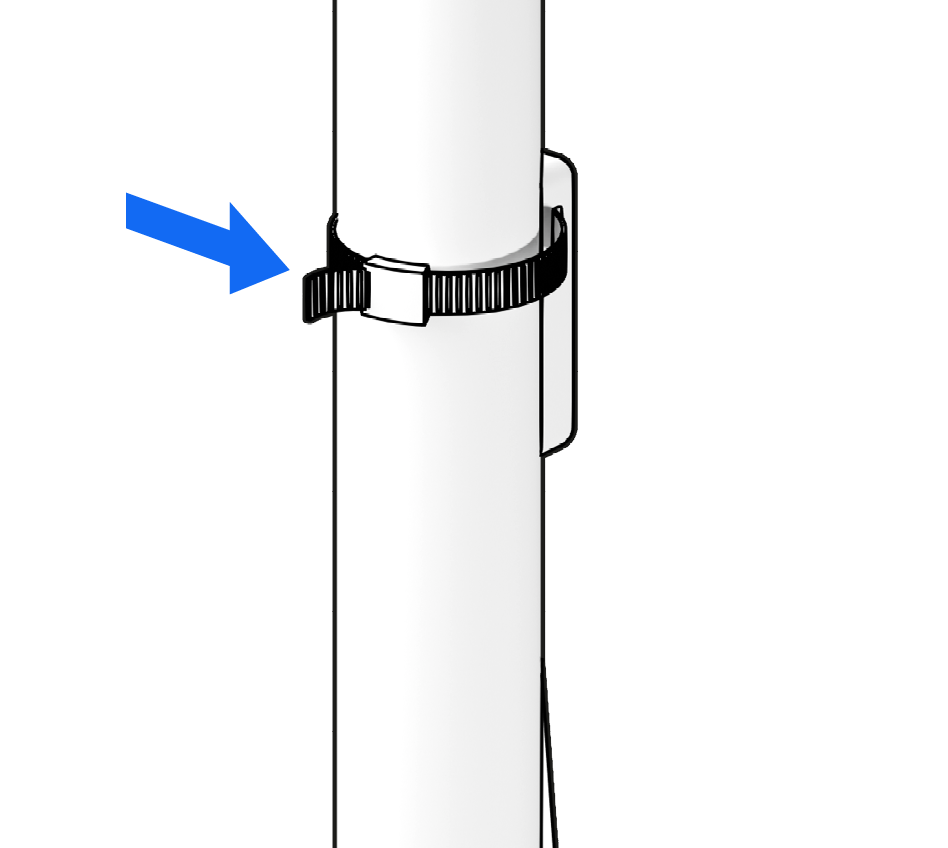

Place the sensor on clear area of the flow pipe at the optimum distance from water heater.

Note: Do not place sensor on return pipe.

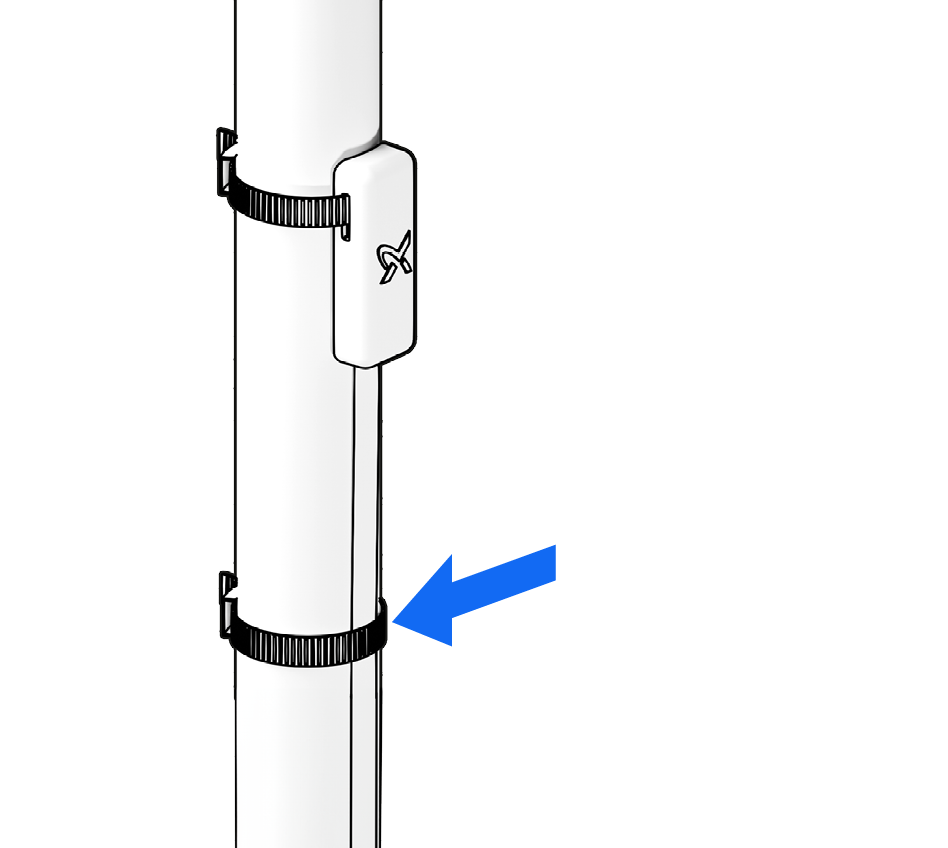

Secure the sensor position by closing the strap so the sensor has always good contact with pipe surface.

Note: Do not use any additional materials such se thermal paste.

WARNING: Loose sensor cable is a trip hazard.

Secure it with additional straps.

- The pump and external sensor are now ready for operation. When electrical connection is made, pump starts and learning process begins.

- The pump requires a permanent power supply. Do not connect the pump to an additional controller or timer.

- If the power supply is interrupted:

– all learning patterns are deleted

– the previously set control mode is retained.

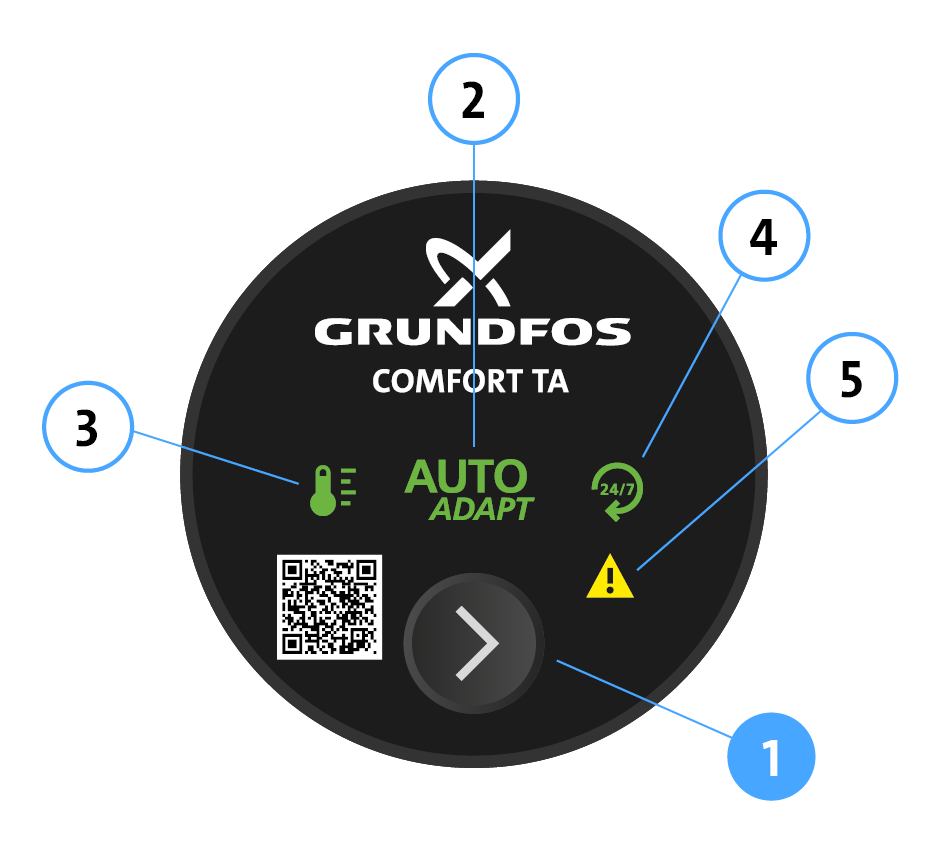

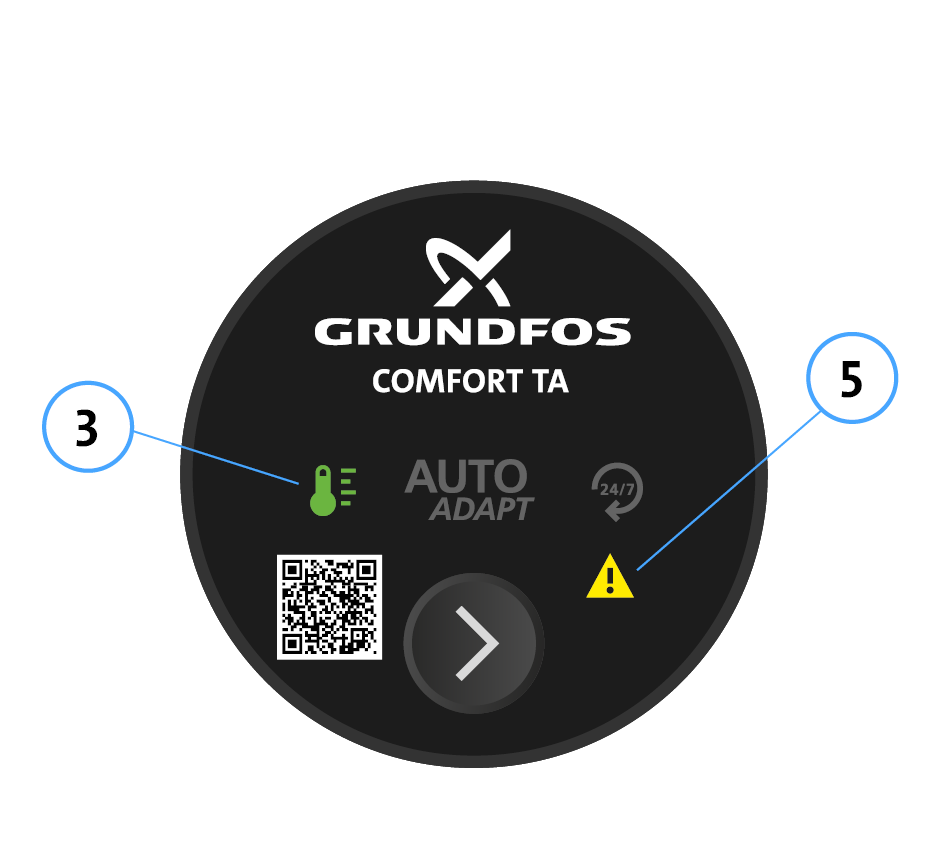

(1) Arrow button

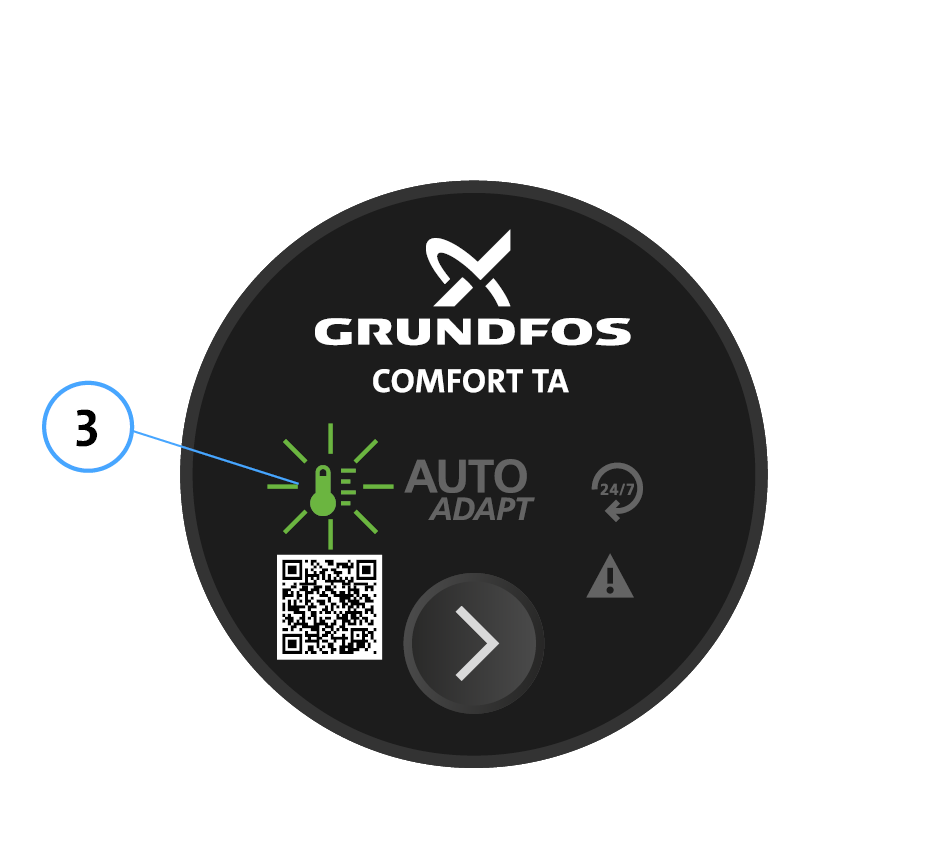

(2 ) LED AUTOADAPT mode

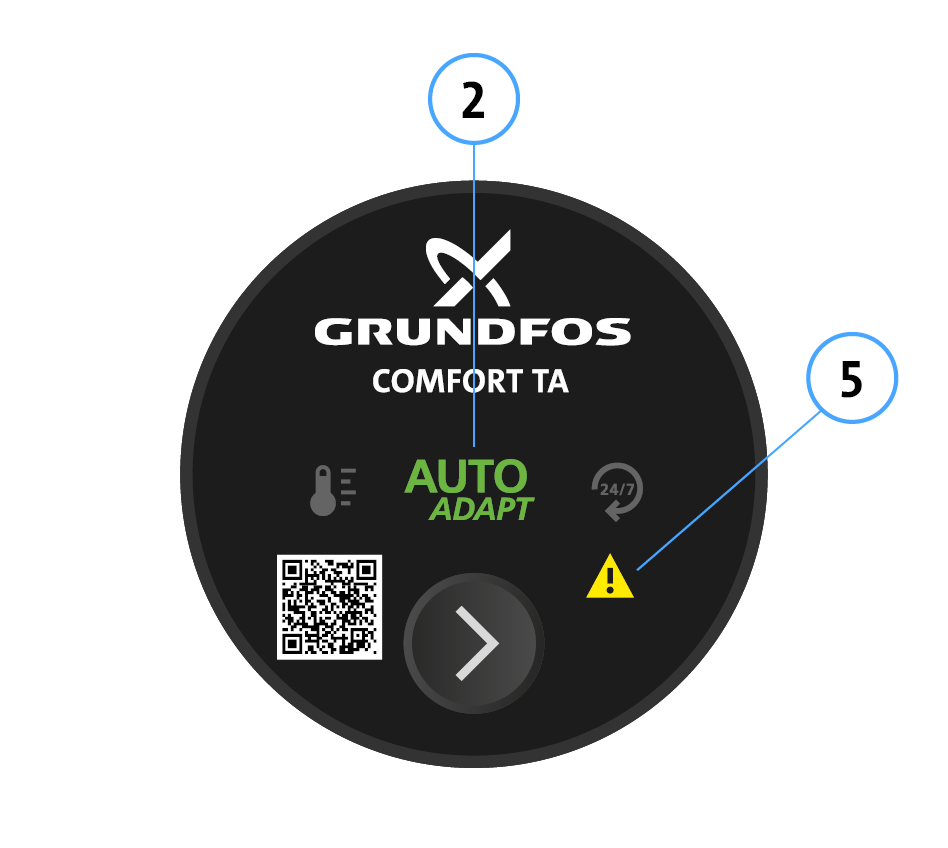

(3) LED TEMPERATURE+ mode

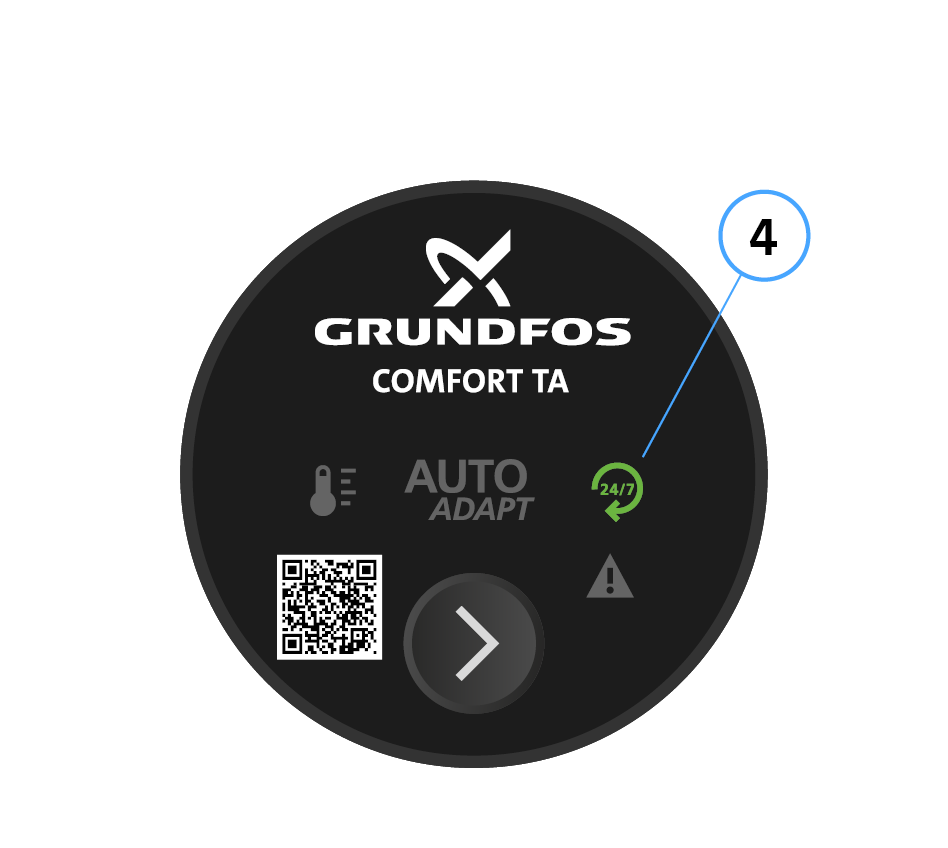

(4) LED Continuos operation 24/7 mode

(5) LED Warning

- Pump operates

- LED (2) AUTOADAPT mode has steady green light.

- Press Arrow button (1) until requested control mode is selected:

AUTOADAPT mode: LED (2) has steady green light.

(See chapter "AUTOADAPT Mode")

TEMPERATURE+ mode: LED (3) has steady green light.

(See chapter "TEMPERATURE+ Mode")

CONTINUOS 24/7 mode: LED (4) has steady green light.

LED (2) steady green light. Pump operates in AUTOADAPT mode.

LED (2) flashes green light. Pump is stopped and waiting in AUTOADAPT mode for condition to resume operation (e.g. water to cool down, time of the day when is predicted for water to be used or tapping detection if it is in vacation mode)

LED (2) AUTODAPT has steady green or flashing light, depending on conditions. LED (5) Warning has steady yellow light. External sensor is broken. Pump operates in temperature mode based on only internal sensor. Vacation mode is not possible.

LED (3) TEMPERATURE+ has steady green light. Pump operates in TEMPERATURE+ mode

LED (3) TEMPERATURE+ flashes green light. Pump is stopped and waiting in TEMPERATURE+ mode for condition to resume operation (water to cool down or tapping detection if it is in vacation mode)

LED (3) TEMPERATURE+ has steady green or flashing light, depending on conditions. LED (5) Warning has steady yellow light. External sensor is broken. Pump operates in TEMPERATURE mode based on only internal sensor. Vacation mode is not possible.

Press and hold Arrow button (1) for 5 seconds. Release arrow button. LED (2) AUTOADAPT mode has steady green light. All learning patterns are deleted.

DANGER! Electric shock can kill!

- Before working on the pump, disconnect from the power supply and secure against reconnection.

- Check that no voltage is present.

DANGER! Pressurised system!

- Before working on the motor or pump connections, close the shut-off valves.

WARNING! Risk of scalding due to hot water!

- Avoid direct contact with escaping hot water.

- The pump housing can similarly reach a high temperature due to the hot medium being pumped.

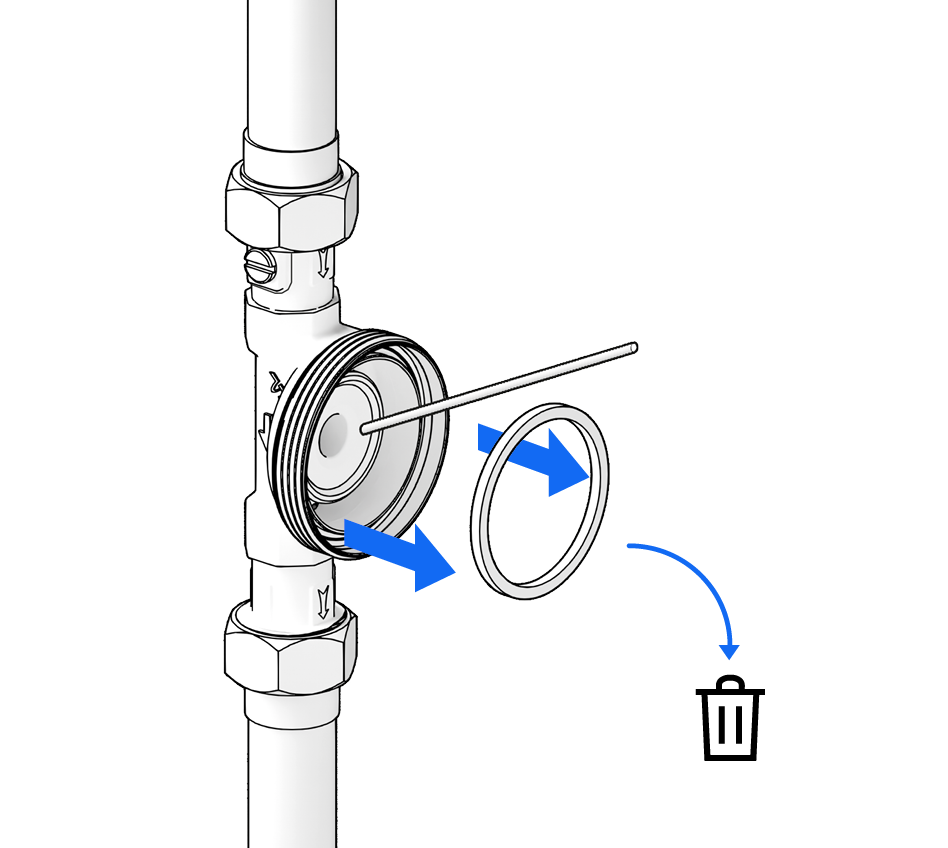

- Whenever the motor is opened up, replace the seal in the pump housing.

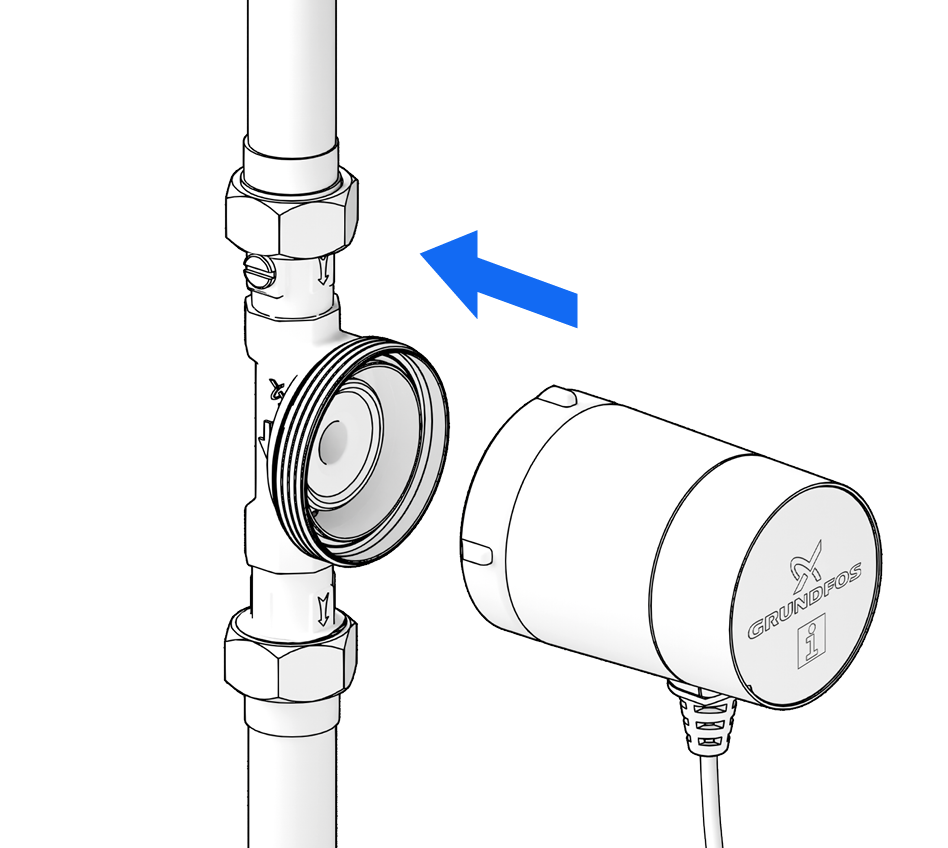

For maintenance, first close the shut-off valves.

Unscrew the motor from the pump housing …

… Carefully lift the rotor off the bearing pin.

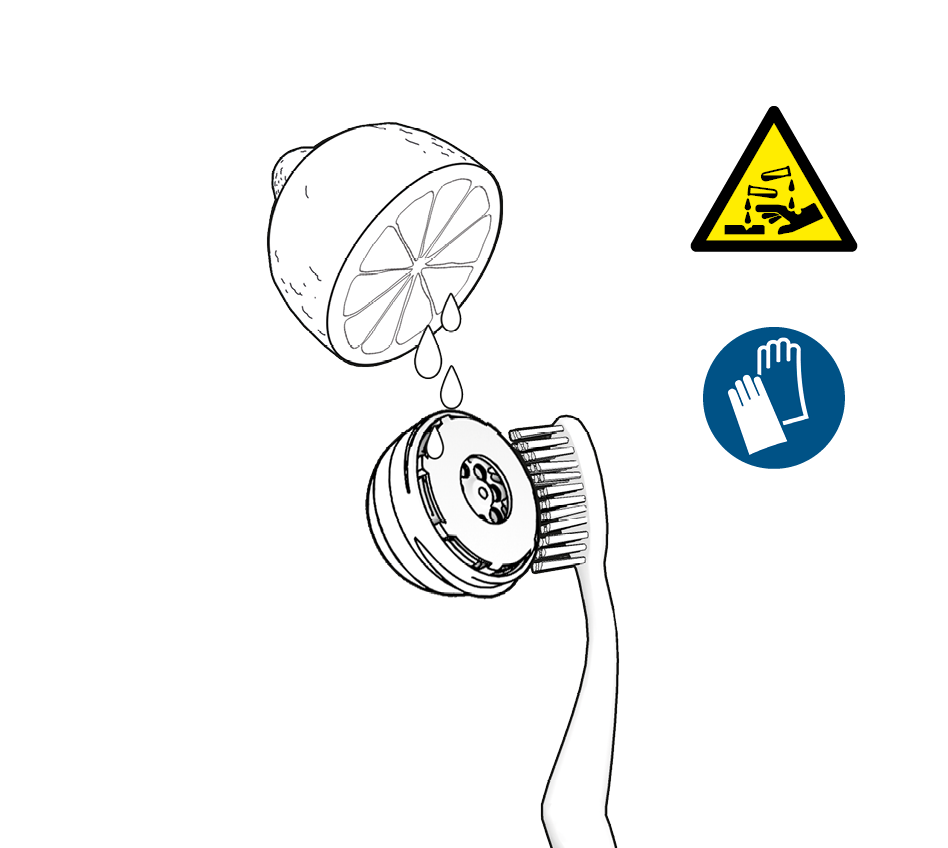

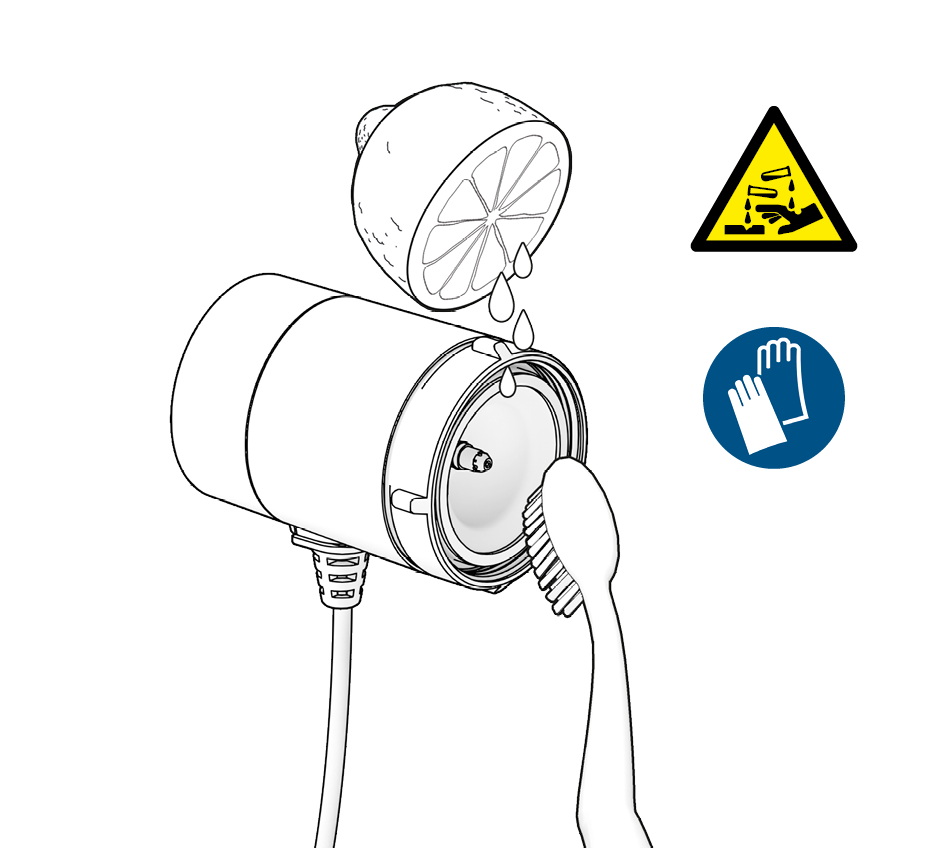

Using a limescale remover, free the rotor and separating cap of limescale. Use only soft, non-metallic tools (e.g. brush, cloth, toothpick).

Reposition the rotor on the bearing pin.

Remove the old seal.

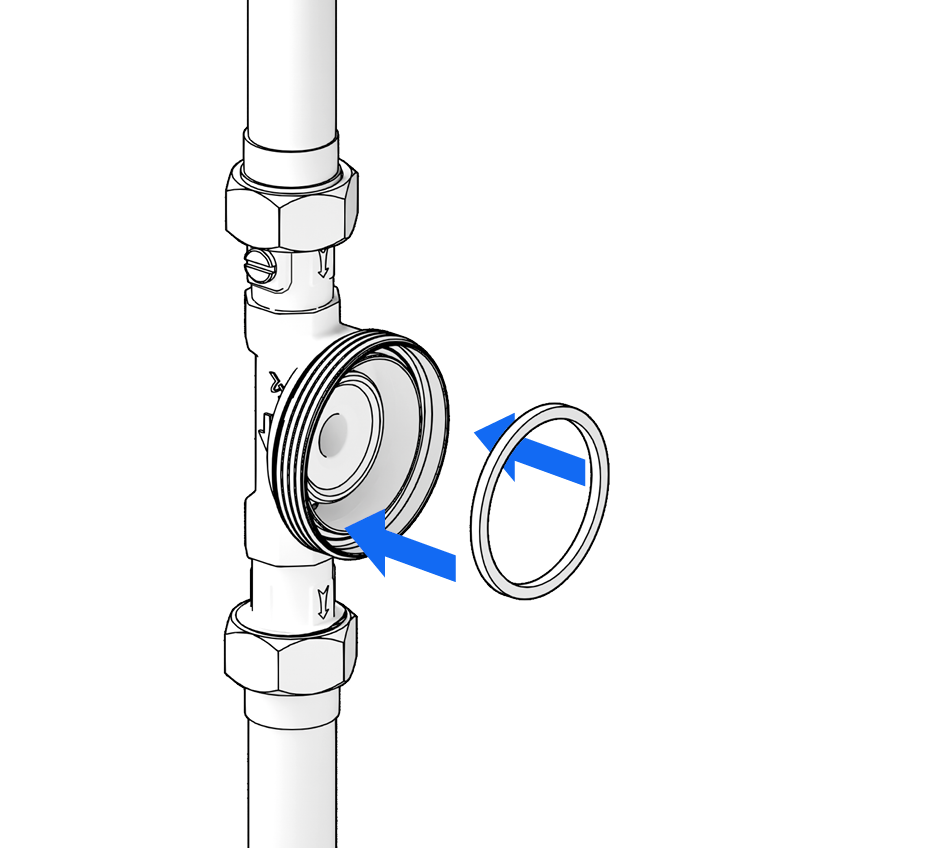

Insert new seal into the pump housing

… and reattach the motor to the pump housing.

Retighten the union nut

(max. 20 Nm).

Slowly open the shut-off valves again.

To vent any remaining air, switch the pump on and off several times …

… and open the DHW tap several times …

… until the pump runs quietly.

The correct disposal of packaging in separate collection is

fundamental for optimization of the recycling processes. The packaging

materials should be correctly disposed of in separate collection, sorted

and recycled according to the provisions of your local authority. The

symbols included on the packaging material will help you to identify the

material category to perform the correct separation.

See what packaging materials Grundfos products use and how to correctly dispose of them by clicking on this link:

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km.

37.500 Centro Industrial

Garin 1619 Garín Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen

Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Bosnia and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A,

BH-71000 Sarajevo

Phone: +387 33 592 480

Telefax: +387 33 590 465

www.ba.grundfos.com

e-mail:

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar

Castelo Branco, 630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street

no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email:

China

GRUNDFOS Pumps

(Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106 PRC

Phone: +86 21 612 252 22

Telefax: +86 21 612 253 33

Colombia

GRUNDFOS Colombia S.A.S.

Km 1.5 vía Siberia-Cota Conj.

Potrero Chico,

Parque Empresarial Arcos de

Cota Bod. 1A.

Cota, Cundinamarca

Phone: +57(1)-2913444

Telefax: +57(1)-8764586

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

Czechia

Grundfos Sales Czechia and

Slovakia s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail:

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Trukkikuja 1

FI-01360 Vantaa

Phone: +358-(0) 207 889 500

France

Pompes GRUNDFOS

Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier

(Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929

69-3799

e-mail: infoservice@

grundfos.de

Service in Deutschland:

e-mail:

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. AthinonMarkopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung

Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Tópark u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram

Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT. GRUNDFOS POMPA

Graha Intirub Lt. 2 & 3

Jln. Cililitan Besar No.454.

Makasar, Jakarta Timur

ID-Jakarta 13650

Phone: +62 21-469-51900

Telefax: +62 21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin-Miyakoda,

Kita-ku,

Hamamatsu

431-2103 Japan

Phone: +81 53 428 4760

Telefax: +81 53 428 5005

Kazakhstan

GRUNDFOS Kazakhstan LLP

7’ Kyz-Zhibek Str., Kok-Tobe micr.

KZ-050020 Almaty

Kazakhstan

Phone: +7 (727) 227-98-55/56

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku,

135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60,

LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail:

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

Grundfos Pompe România SRL

S-PARK BUSINESS CENTER,

Clădirea A2,

etaj 2, Str. Tipografilor, Nr. 11-15,

Sector 1,

Cod 013714, Bucuresti, Romania,

Tel: 004 021 2004 100

E-mail:

www.grundfos.ro

Serbia

Grundfos Srbija d.o.o.

Omladinskih brigada 90b

11070 Novi Beograd

Phone: +381 11 2258 740

Telefax: +381 11 2281 769

www.rs.grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Phone: +65-6681 9688

Telefax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D

821 09 BRATISLAVA

Phona: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS LJUBLJANA, d.o.o.

Leskoškova 9e, 1122 Ljubljana

Phone: +386 (0) 1 568 06 10

Telefax: +386 (0)1 568 06 19

E-mail:

South Africa

Grundfos (PTY) Ltd.

16 Lascelles Drive,

Meadowbrook Estate

1609 Germiston, Johannesburg

Tel.: (+27) 10 248 6000

Fax: (+27) 10 248 6002

E-mail:

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Telefax: +41-44-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama

9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve

Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail:

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Телефон: (+38 044) 237 04 00

Факс.: (+38 044) 237 04 01

E-mail:

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971 4 8815 166

Telefax: +971 4 8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

Uzbekistan

Grundfos Tashkent, Uzbekistan

The Representative Office

of Grundfos Kazakhstan in

Uzbekistan

38a, Oybek street, Tashkent

Телефон: (+998) 71 150 3290 / 71 150 3291

Факс: (+998) 71 150 3292