-

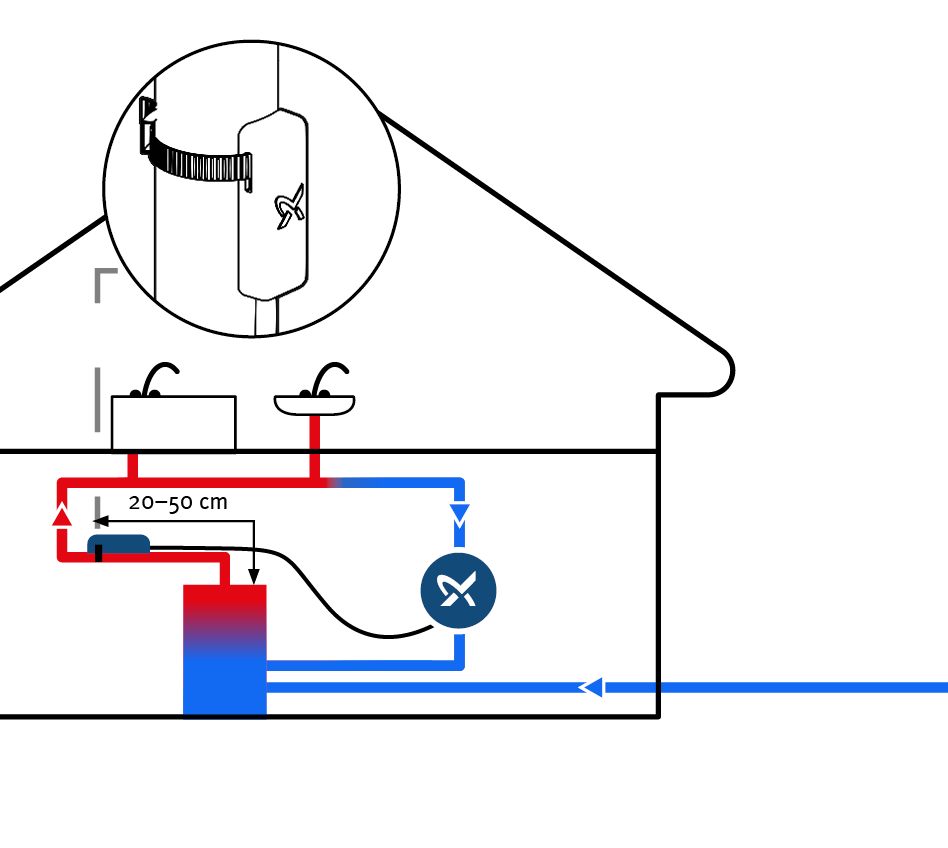

The external sensor should be installed on the DHW flow (regardless of the type of DHW heat source). The optimum distance from the external sensor to the DHW heater is 20–30 cm (for a plastic/composite pipe) or 50 cm (for a metal pipe). If the flow line exits vertically from the DHW heater, fit a U-bend upstream of the sensor installation location. Otherwise DHW draw-off will not be detected as the temperature change will be too small.

- If a mixer tap is installed, install the external sensor at an appropriate distance downstream of the mixer tap.

- Install the external sensor only on a straight section of pipe (without bends, corrugations, taps or tee-joints).

- The DHW heating system must deliver a constant temperature level of at least 120 °F (48 °C) (except during night setback). Otherwise, the required level of DHW convenience cannot be guaranteed.

- Branched pipework systems (multiple-circuit systems) must be hydraulically balanced by means of regulating valves in the return lines. Otherwise, the level of convenience may be adversely affected as the pump may switch off too early.

The pump requires a permanent power supply.

Do not connect the pump to an additional controller or timer.

If hot water is not available directly after opening a tap, turn the tap off again and wait for circulation to start.

DO NOT PULL

- External sensor is already built in and connected with the pump.

- Make sure you don’t damage the sensor cable.

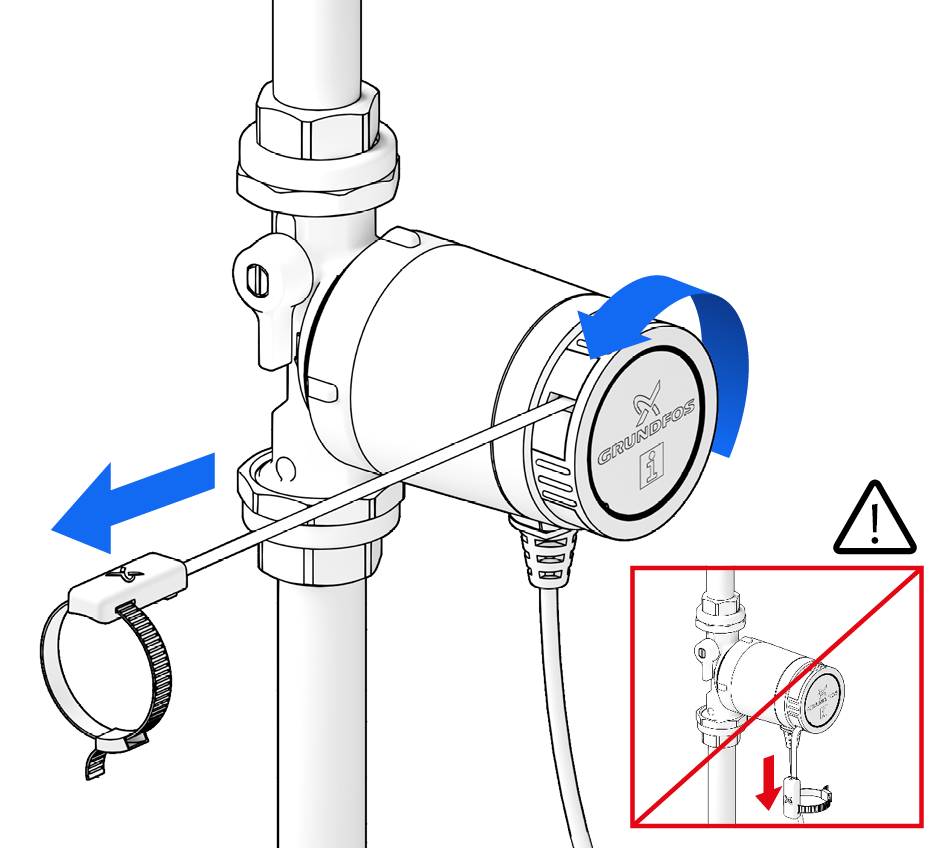

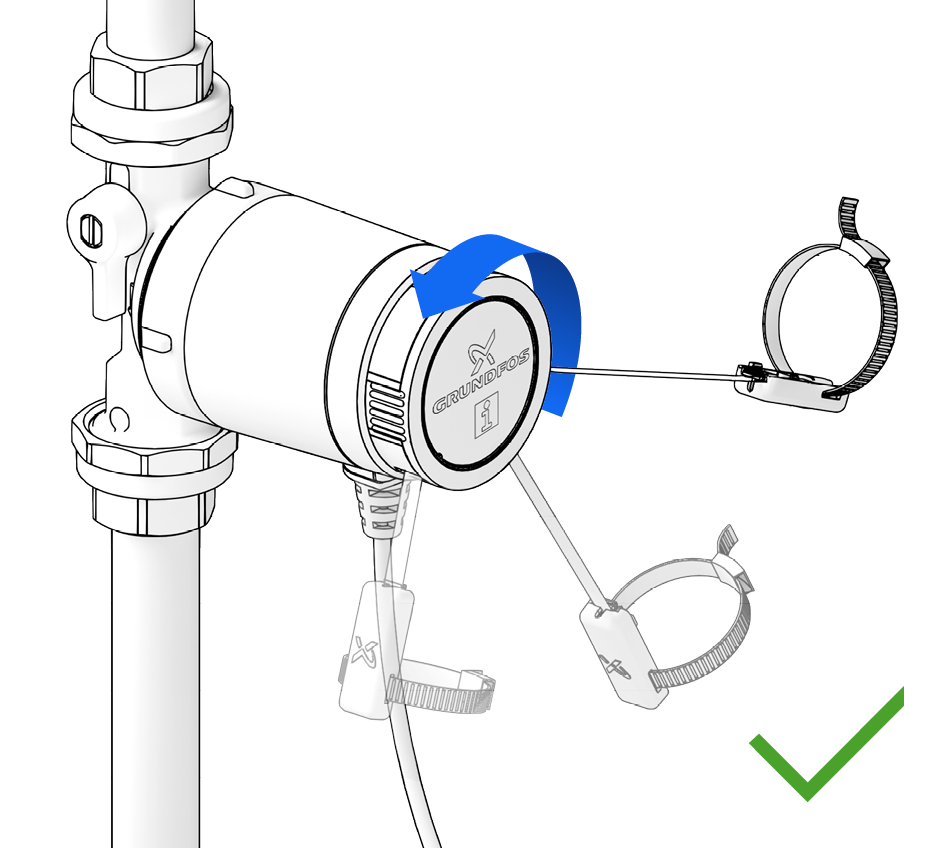

Gently unwind the sensor cable counterclockwise to desired length. The maximum length is 8ft (2.5m).

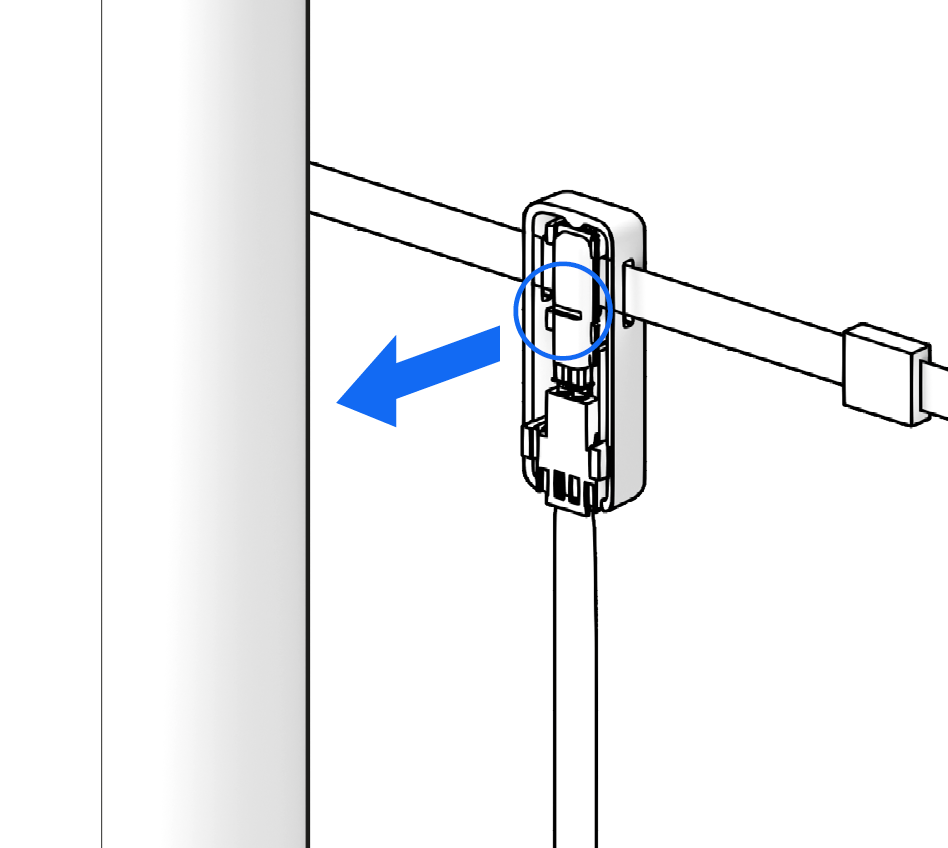

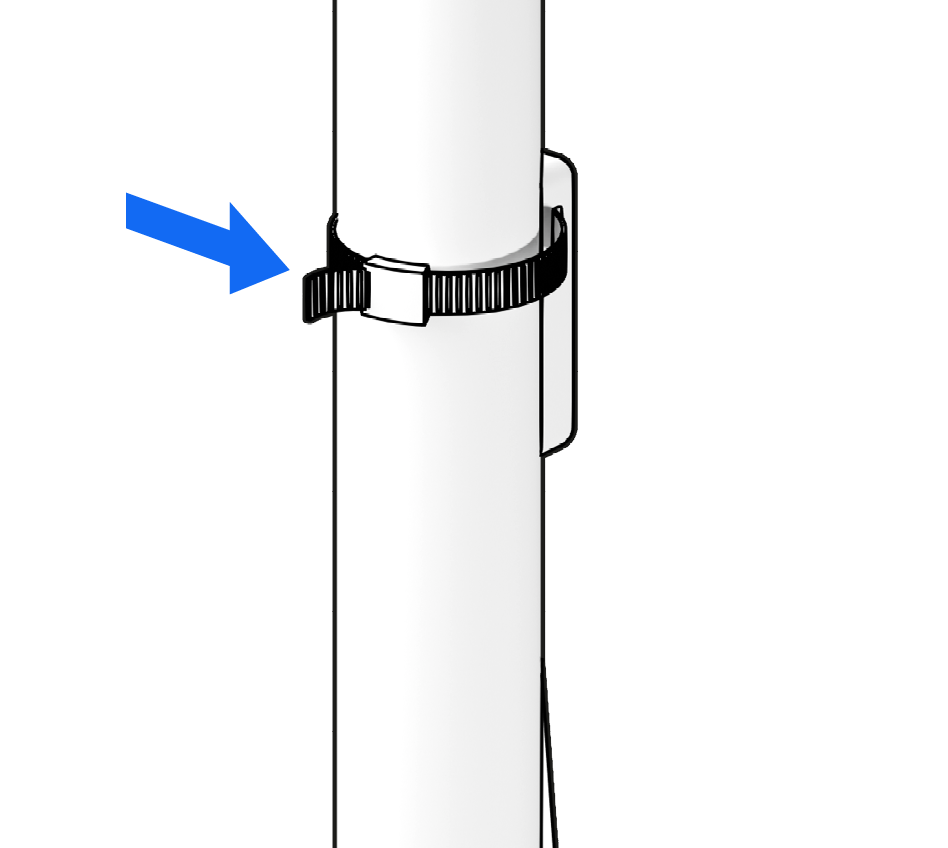

Place the sensor on clear area of the flow pipe at the optimum distance from water heater.

Note: Do not place sensor on return pipe.

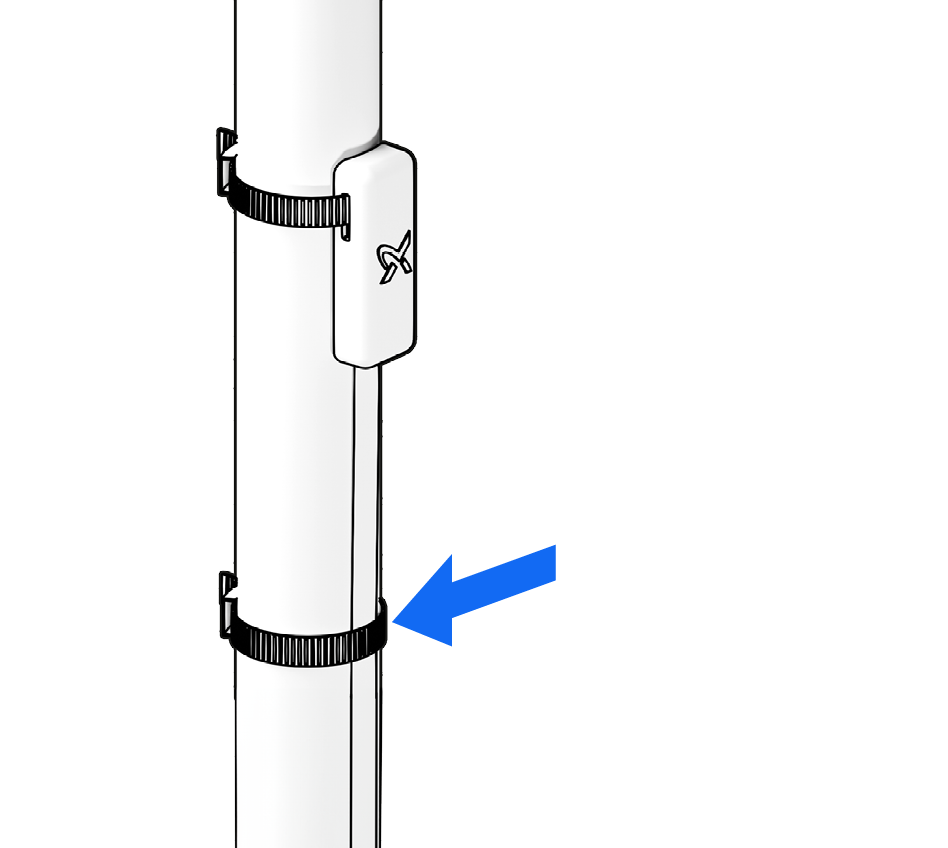

Secure the sensor position by closing the strap so the sensor has always good contact with pipe surface.

Note: Do not use any additional materials such se thermal paste.

WARNING: Loose sensor cable is a trip hazard.

Secure it with additional straps.

- The pump and external sensor are now ready for operation. When electrical connection is made, pump starts and learning process begins.

- The pump requires a permanent power supply. Do not connect the pump to an additional controller or timer.

- If the power supply is interrupted:

– all learning patterns are deleted

– the previously set control mode is retained.